Come visit our 1000 m2 stand and see our world class solutions at booth #1B69.

It has been six years since we last attended this event due to the Covid-19 pandemic, but we have continued developing new machinery, and improving the existing one.

Diverse equipment will be exhibited during Interpack 2023, including tempering machines, cooling tunnels, moulding and steel belt lines. Our newest tempering machine, StellaNova, will be among them; it has unique features: it is built entirely in stainless steel materials and can save up to 30% energy compared to traditional tempering machines.

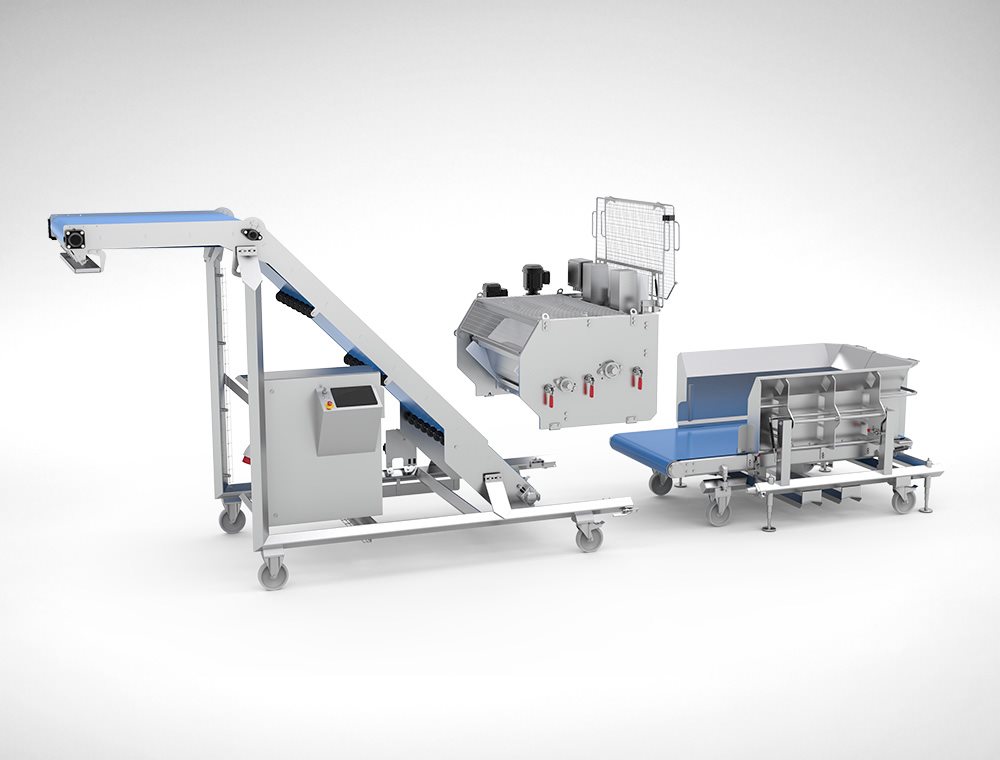

A complete bakery line comprised of an Alice Classic depositor and extruder, with a highspeed wire cutter and an Aasted dough feeder, will be displayed as well as an Alice II, a flexible machine that enables a quick changeover between productions.

Moreover, the company will present new enrobing and moulding solutions. Further information on these products will be released at the fair.

What to expect at Interpack 2023

Explore energy savings across your entire production

An optimized and efficient energy conversion can provide significant energy savings across your entire production, lowering your operational costs and driving your sustainability agenda.

| LEARN MORE |

What if ... the future of chocolate tempering is now?

Radically improve your production and learn if the best thing about the new StellaNova tempering machine is that it can reduce your chocolate waste by up to 75%, or that it reduces your cooling time up to 40%.

| CHECK OUR STELLANOVA |

Explore energy savings across your entire production

An optimized and efficient energy conversion can provide significant energy savings across your entire production, lowering your operational costs and driving your sustainability agenda.

| LEARN MORE |

Complete bakery solutions

Alice™ II extruder

Alice™ II is an entirely stainless steel depositor and extruder. The new solution helps you create the best bakery and confectionery products and improves your productivity.

| DISCOVER MORE |

Alice™ Classic extruder

Alice™ Classic with a high-speed wire cutter is a combination of a sophisticated high-speed wire cutting mechanism and a new extrusion head for high capacity and accurate dosing.

| DISCOVER MORE |

Aasted Dough feeder

The two-belt modular belt system is the most flexible solution for dough feeding. Provides complete control of the height and speed of dough supply while being extremely gentle.

| DISCOVER MORE |

The latest in tempering!

Aasted StellaNova® is the only tempering machine of its kind. It revolutionizes the tempering process as we know by separating cooling and shearing processes. Meaning you can cool chocolate to a remarkably low temperature while maintaining the same amount of crystals. StellaNova® lets you achieve shorter cooling time and raising production line output up to 40%.

| LEARN MORE |

A testimony to customer feedback

The Aasted Smart Control™ interface is a result of valuable feedback, comprehensive analysis, and close collaboration with experts and customers. This solution stood out from over 8,500 entries and won the Red Dot Award, worldwide known as a seal of quality, for good design.

| LEARN MORE |

Learn from others' stories

"Durable and reliable"

– Chocolates Valor

Any Aasted line – whether producing chocolate, bakery or confectionery – is a carefully coordinated interplay of technical solutions. Take the Spanish chocolate company Valor, founded in 1881. 30 years ago, Valor invested in an Aasted moulding line and the line is still in perfect condition churning out tons of chocolate per year with a minimum amount of maintenance.

| LEARN MORE |

"Fit for Royals"

– Sv. Michelsen Chocolate

Sv. Michelsen Chocolate is a danish family-owned company that is known for being a purveyor to the royal household for more than 25 years. But the connection to Aasted goes back much further. Three generations ago, the chocolate company was among the first to implement an Aasted Enrober that has since, been a smooth running and seamless part of their chocolate production line.

| LEARN MORE |

"The highest quality"

– Friis-Holm Chocolate

If you ask the International Chocolate Award winner, chocolatier Mikkel Friis-Holm, the quality of the final product must take priority over how fast the production is. Friis-Holm Chocolate has found that mindset reflected in Aasted’s engineers whose insights into tempering, depositing and cooling have global renown. Moreover, it is Aasted’s friendship and service that make the collaboration great.

| LEARN MORE |

Get inspired on YouTube

At Aasted, we provide you with the best solutions, but also with the unique knowledge based on 100 years of experience. We have a great variety of machines, solutions, services and countless possibilities depending on your specific needs. We offer you the opportunity to become familiar with our machines and discover the right one for your production.

| VISIT OUR YOUTUBE CHANNEL |

Thank you for booking a meeting, we will return to you soon with a confirmation email!

Something went wrong while sending the form. Please try again or get in contact with us via mail or phone.

{{ ::group.title }}

Aasted News

{{::newsItem.Heading}}

{{::newsItem.Teaser}}

{{::newsItem.LinkText}}