Efficient and effective

The ultimate combination of hygiene, high speed and capacity

Alice™ Classic with a high-speed wire cutter is a combination of a sophisticated high-speed wire cutting mechanism and a new extrusion head for high capacity and accurate dosing of dough with high amounts of inclusions. The new extrusion head design and its features perfect your dosing performance and is extremely gentle in extruding dough.

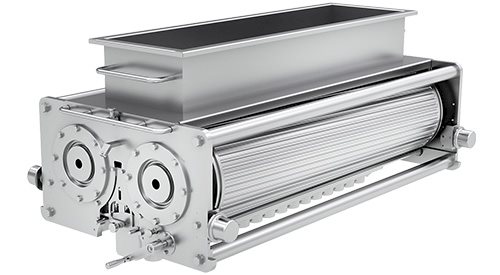

Dosing performance

The new extrusion head design and its features perfect your dosing performance, by being extremely gentle while handling or extruding dough. Large rollers provide gentle dough handling while the stainless steel filler block ensures a reliable and gentle dough extrusion with accurate weight control across the band.

1. Filler block

The filler block is positioned with a cam driven parallel up/down motion.

After lowering the filler block it can be slid sideways out onto a trolley.

2. Gentle feeding rollers

Large feed rollers with a grooved pattern ensure efficient grip but a gentle dough handling and ensure even weight across the entire width of the machine.

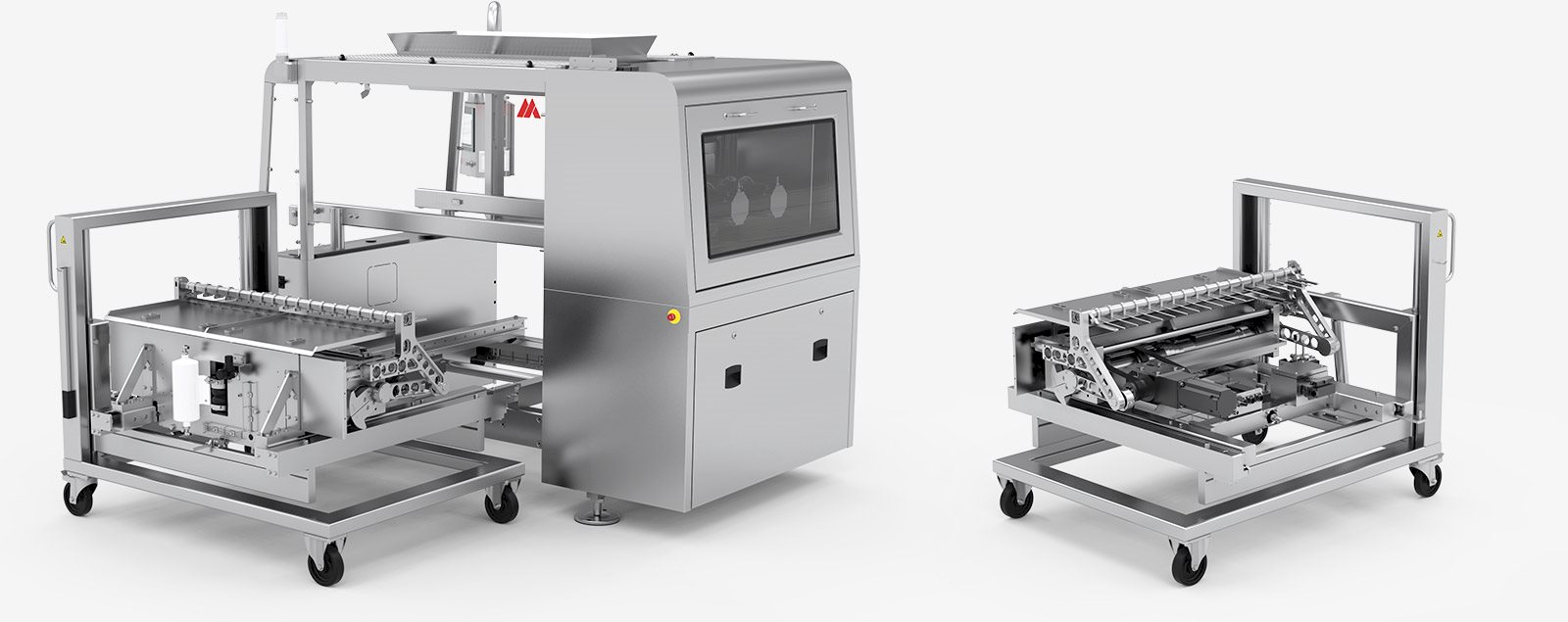

Off-line function for easy cleaning

Alice™ Classic with a high-speed wire cutter

Alice™ Classic with a high-speed wire cutterhas an off-line function that allows you to

remove the extruder head.

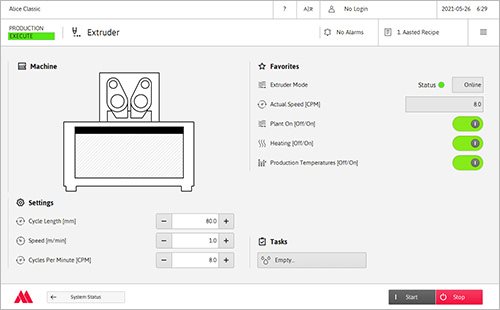

Adjustable cutting performance

It is possible to adjust the following cutting motion

parameters on the fly:

parameters on the fly:

- Up to 250 cuts/min.

- Cutting length from 50 to 120 mm

- Vertical drop height from 5 to 15 mm

- Center line from 0 to 20 mm

- Trimming of the pressure between

- Wire and cutting die from 0 to 20 mm

Off-line function for easy cleaning

Alice™ Classic with a High-speed wire cutter

Alice™ Classic with a High-speed wire cutterhas an off-line function that allows you to

remove the cutting mechanism. The off-line

function significantly reduces your downtime

and potentialy increases your capacity.

Award-winning intuitive User Interface

While other machines have complicated to use interface, our new patented software has a user-friendly one. The interface is developed for users by users and is specially produced by Aasted for the bakery industry.

| LEARN MORE |

Read about the 4 most critical challenges in bakery production

The challenges in the bakery industry are centered around continuously changing environmental hurdles, financial constraints and an increasingly global customer base that are forcing flexibility. These changes demand many industrial bakeries to innovate and associate a more flexible production capacity.

| GET YOUR FREE WHITE PAPER HERE! |

Welcome to Aasted

Visit Aasted Tehnology Center and experience our solutions for yourself

Aasted Technology Center is fully modernized with the latest processing equipment. Not only can you see the Alice™ Classic in action, but you can also combine it with other processing equipment. Fill in the form below or contact our sales manager. Start exploring your production possibilities.Let us inspire you – so you can make delicious possible!

| LEARN MORE |