Tempering is in our DNA

Revealing the most striking advance in the chocolate tempering process since 1946.

Following 1946, when Dr. Kaj Christian Sophus Aasted invented the world’s first patented continuous chocolate plate temperer, Aasted has been continuously advancing and perfecting the chocolate tempering process. With more than 100 years of experience in the chocolate industry, our tempering machines are embedded with unique know-how from dedicated and passionate engineers and chocolate specialists.

We are proud to introduce you to a new standard in the chocolate tempering process!

Introducing a new standard

StellaNova – unsurpassed quality in chocolate tempering with a brand new process.

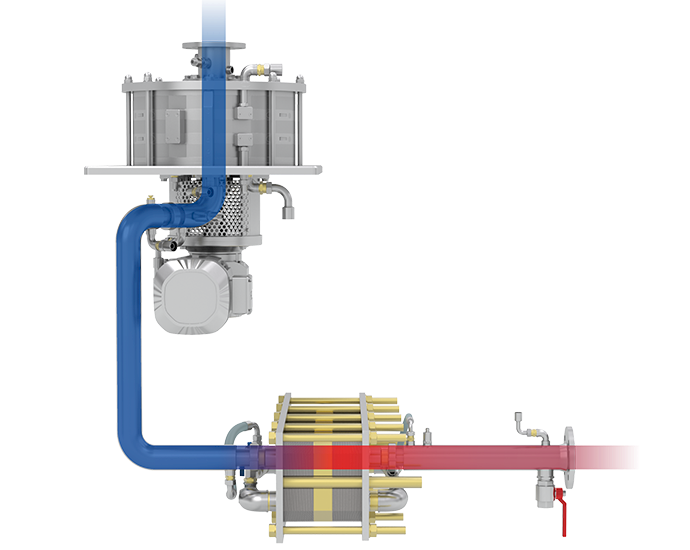

The new StellaNova, like no tempering machine before, has separate cooling and shearing processes. It’s now possible to set the exit temperature as low as 27ºC while keeping the highest quality of crystals; you can raise production line output up to 40% by needing much shorter cooling time. The machine is built entirely in stainless steel and has a unique planet wheel design that ensures 400% more shear without creating additional shear heat and saves up to 30% of energy compared to the traditional tempering machines.

- Hygienic stainless steel design

- Contains 75% less chocolate than traditional tempering machines

- The highest quality in chocolate tempering

- Does not create ß4 crystals

- Shorter cooling time, hence more throughput in the production line

- Smaller motor and no required reheat saves up to 30% of energy

- No add-ons required

- Compact design

- Easy to operate

Stainless steel hygienic design

StellaNova is the only tempering machine in the market built entirely in stainless steel materials, from its unique planet scraper wheels to all other elements that are in contact with the chocolate. Being stainless steel makes it significantly safe and available to use for food production, in other words, it lives up to the latest food-grade standards.

StellaNova saves up to 30% energy

The new StellaNova has a smaller motor and column. The new design holds up to 75% less chocolate while still being extremely efficient.

StellaNova’s chocolate tempering process doesn’t require a reheat. Combined, with having a smaller motor and stack, these two factors save up to 30% energy, compared to traditional tempering machines.

Achieve up to 40% shorter cooling time

The new StellaNova is one of a kind chocolate tempering machine. It has separate cooling and shearing processes. Meaning you can cool chocolate to a remarkably low temperature while maintaining the same amount of crystals. StellaNova lets you achieve shorter cooling time and raising production line output up to 40%.

Pushing boundaries in tempering

Unmatched degree in crystallization

With the new StellaNova, it’s now possible to choose exit temperature, as low as 27ºC and temper index separately, while maintaining the highest quality of crystals, giving you the possibility to raise production line output up to 40% by needing much shorter cooling time.

400% more shear with unique planet scraper wheel design

The new planet scraper wheel design ensures a greater shear, more uniform shear velocity and no possibility for the mass to bypass the cooling surfaces. Further, the innovative design provides 400% more shear without creating additional shear heat and significantly saves energy.

The mass landscape.

One type fits all

With the brand new StellaNova you can temper any type of chocolate. StellaNova is a machine that can handle all chocolate viscosities and fat contents.

New patented software

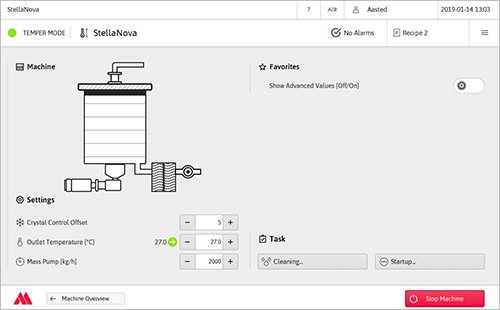

The most simple and user-friendly interface ever made for a tempering machine.

While other tempering machines have complicated to use interface, our new patented software has a user-friendly and intuitive one. With the new software, it is effortless to adjust the exit temperature and the temper index separately. The user interface is developed for users by users and is specially produced by Aasted for the chocolate industry.

Experience StellaNova

Experience the new StellaNova, a solution that transforms the tempering process. See how this solution and it's brand new tempering process separates the cooling and shearing processes without sacrificing the quality of your chocolate, reduces energy use and extends your production line output!

Read about the 10 most critical challenges in tempering

For the past 100 years, we have been working with tempering and have discovered that everything in chocolate production revolves around tempering. It is the starting point that defines your processing path, and it determines the quality.

| GET YOUR FREE WHITE PAPER HERE! |

What if ... the future of tempering is now?

Radically improve your production and learn if the best thing about the new StellaNova is that it can reduce your chocolate waste by up to 75%, or that it reduces your cooling time up to 40%.

| DISCOVER MORE |

Welcome to Aasted

Visit Aasted Tehnology Center and experience the StellaNova technology.

Witness for yourself the StellaNova and its capabilities of setting the chocolate exit temperature as low as 27ºC while maintaining the highest quality of crystals.

Interested in understanding the full scope of benefits from how the StellaNova processes your chocolate?

Aasted Technology Center is fully modernized with the latest processing equipment. Not only can you see the StellaNova in action, but you can also combine it with other processing equipment. Fill in the form below or contact our sales manager. Start exploring the possibilities of StellaNova.

Let us inspire you so you can make delicious possible!

| LEARN MORE |

StellaNova® temper - Related documents

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.