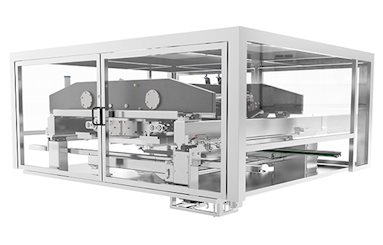

SE14 Depositor

The SE14 allows you to deposit solid and filled chocolates. Available in different variations the SE14 series suits large scale production with its high speed and accuracy.

Aasted's legacy in producing superior chocolate depositors and center depositing machines dates back to 1950, when we innovated the world’s largest moulding line. Our chocolate depositing machines offer minimized production time and enhanced quality due to precision engineering.

We provide a comprehensive range of chocolate depositor machines, ensuring only top-quality and high-precision machinery. Whether it's standalone or built-in machinery, our chocolate depositor program provides versatile solutions that can be customized to your specific needs.

Our range covers all requirements, whether you need center filling, bottom, one or many colors, or aerated masses. Our chocolate depositor machines are designed to handle large-scale operations with the flexibility to adapt as your business evolves. Whether it's for cookie dough depositing or as a universal depositor, our equipment is the ideal solution for your dynamic needs.

Our design emphasizes ease of cleaning and efficiency, providing a chocolate depositor machine that enhances your creative freedom while boosting your production efficiency.

Depositing of dark, white, milk chocolate, fat masses or even aerated masses into moulds, covers what depositing is all about. Depositing can be taken out at a slow pace for smaller production lines in different shapes and with various inclusions, or at high speed with simple masses - or the other way around. Many chocolate depositors can be tailor-made and often adapt to existing moulding lines.

With Aasted chocolate depositors, you have many options to choose from, depending on what your needs are. If you have a production line that you are likely to change, implement new machines and move around, a C-frame chocolate and other mass depositor machine is recommended. Chocolate depositors from Aasted serve all purposes, from being flexible, movable, dynamic, and of high-quality with the newest technology.

The FrozenCone® technology was invented in 1986 by Mr. Lars Aasted and originally launched in 1992. This revolutionary technology maintains its leading edge today as the only cold-pressing system on the market, with patented individual movable plungers, perfectly designed shell edges, the highest production speed, and completely sanitary design, without chocolate waste. The frozen cone even manufactures your designed shell edges without knives or roller scrapers.