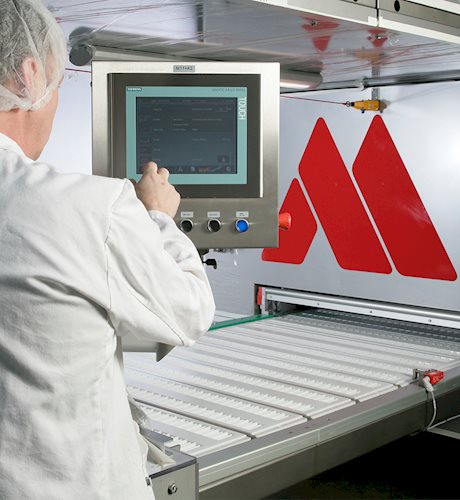

Universal Line

Designed to handle all kinds of moulding from solid to centre fillings, inclusions, caramel, one-shot, triple-shot, and aeration. The Aasted Universal Line is available with several add-ons including the patented FrozenCone Shell System. A unique cold-pressing system that you can control entirely in terms of shell thickness, shape and design if desired.

Product Samples

Solid moulding

Moulding of solid products with or without inclusions, with aeration, tablets, couvertures and combination of chocolate types. Moulding of products with solid centres such as wafers, biscuits centres, big inclusions and bars. Traditional inverting moulding of any shell, surprise and easter eggs.

One-shot moulding

One-shot moulding of center or solid filled chocolate articles with various ingredients e.g. nougat and caramel. Also possible in different chocolate types as well as different moulds for different shaped chocolate articles.

FrozenCone® with center

With a FrozenCone® module, the Universal line makes perfectly shaped cold-pressed shells for pralines, surprise eggs, tablets or any other "shell" product. With a ChocoAssort™ module, a robotic technique transfers the chocolate articles from moulds directly into boxes.