StellaNova temper

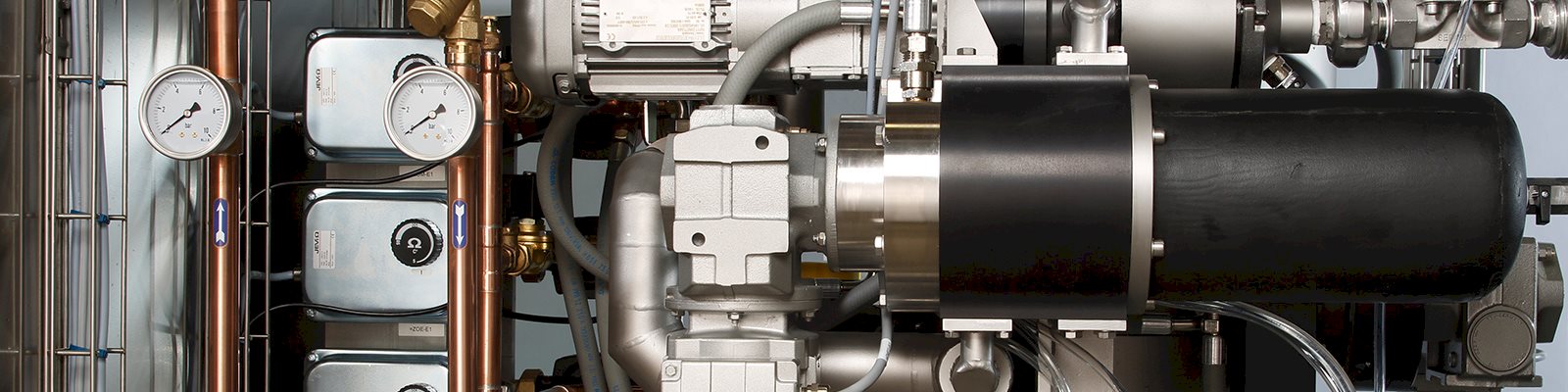

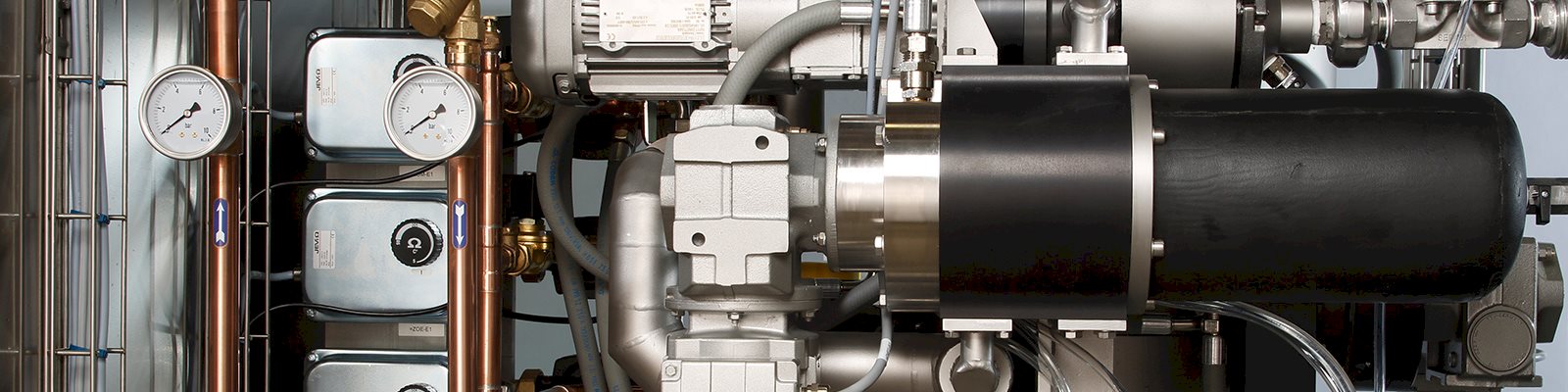

The StellaNova transforms the tempering process by separating the shearing and cooling without sacrificing the quality of your chocolate reduces energy use and extends your production line output!

Here at Aasted we offer traditional industrial chocolate tempering machines as well as innovative solutions that transform the way tempering is done. In 2011 we introduced the world's first energy saving industrial chocolate tempering machine SuperNova Energy that still excels and delivers the finest results - while giving you significant energy reduction and an increase in product's shelf life when compared to traditional chocolate tempering machine methods. In 2018 the creation of StellaNova revolutionized the industrial chocolate tempering machine process by having separate cooling and shearing processes, thus exponentially improving your production.

Radically improve your production and learn if the best thing about the new StellaNova is that it can reduce your chocolate waste by up to 75%, or that it reduces your cooling time up to 40%.

| DISCOVER MORE |

The chocolate tempering machine process induces the correct fat and size crystals in the chocolate. How this process is undertaken affects the glossy appearance, the snap, and the heat resistance of the product. Well-tempered chocolate gives a great appearance, snap, and luscious consistency. However, not so well-tempered chocolate provides the product with a dusty white surface called fat bloom, which leads to a low-quality product.

| LEARN MORE |