Belt Line

The Aasted Belt lines are fully automatic lines, which require only minimal operational supervision and deposit directly onto a cooling, plastic or steel belt. The Aasted belt line produces flawless chocolate chips, chunks, chards, buttons/wafers etc.

Tailor-made to your requirements and made for 24/7 hour production in a hygienic design. All lines are fully tested before shipping minimizing installation time for your benefit. Production capacity from 250 – 6,600 kg/hour.

Product Samples

Chocolate kisses

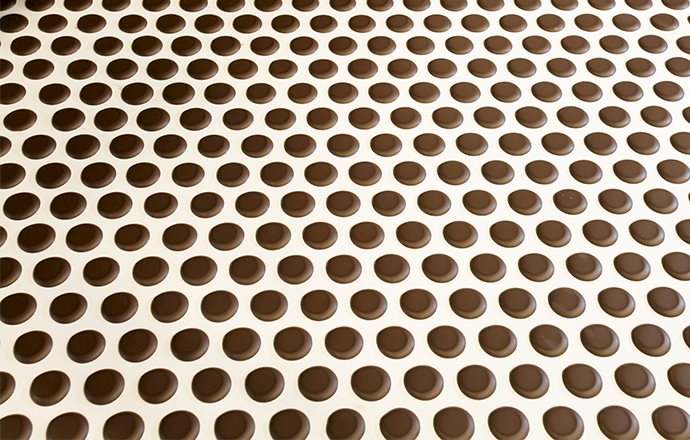

The Belt line deposits single color or multiple color chocolate kisses and buttons, directly onto a plastic or steel belt without using moulds.

Chocolate chips

The fully automatic Belt line deposits uniform and high quality chocolate chips in single or multiple color directly onto a steel or plastic belt.

Chocolate chards

The chocolate cutting devices cut the extruded chocolate into unequal and uneven lengths - suitable for inclusion material in a production line.

Produce chards, chunks and chips

Experience how the Aasted Belt lines produce flawless and high quality chunks, chips and chards. The Aasted Belt lines are fully automatic lines, which require only minimal operational supervision and deposit directly onto a cooling, plastic or steel belt.

The product capabilities are among others: chips, chunks, chards, button/wafers at a capacity from 250 to 6,600kg/hour.

The products from the Aasted Belt line can be used in bakery production lines for ingredient purposes and complimenting e.g. cookies as an indulgence inclusion. They can also be included as an inclusion in e.g. a bar line production, which needs chocolate chunks. The opportunities are countless, and with the Aasted Belt line you are guaranteed the finest quality machinery with minimum downtime.

Production of chocolate chards

Production of chocolate chips

Production of chocolate chunks