Aasted Technology Center

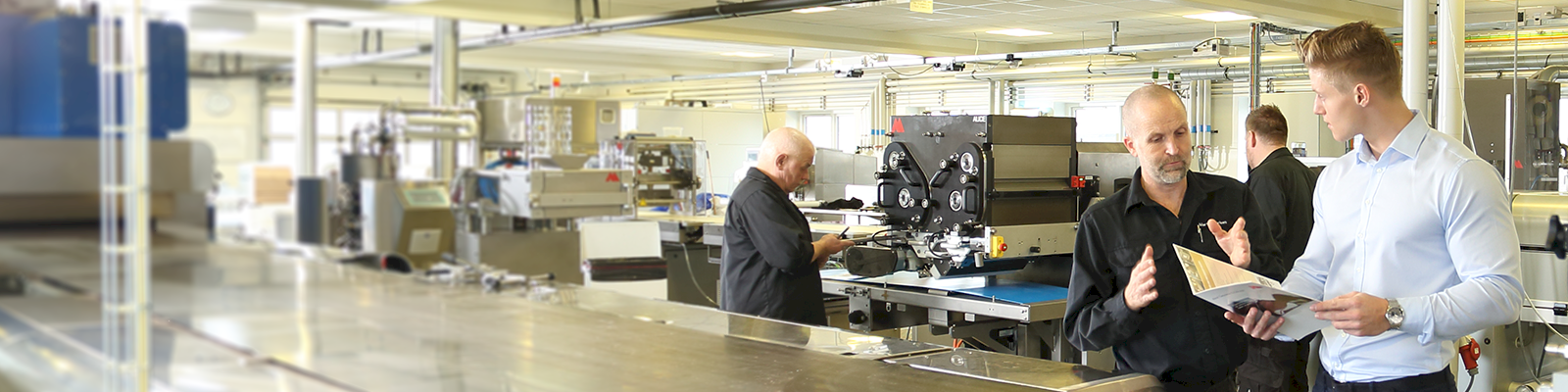

The Aasted Technology Center is an innovative environment consisting of 1200m2. Here product developer and dedicated food specialists help you creating the finest and advanced products. We take pleasure in helping people around the world achieving their every wish and desired goals with our machines. At Aasted Technology Center you can become acquainted with most of our machines and work with them as you please.

Experience and Learning

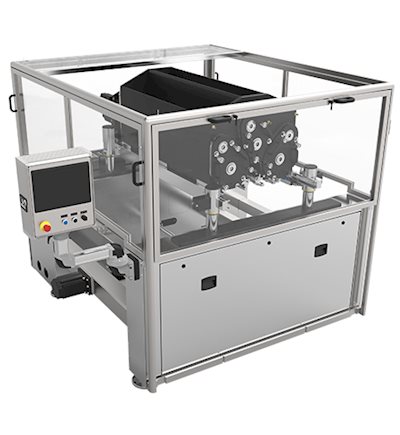

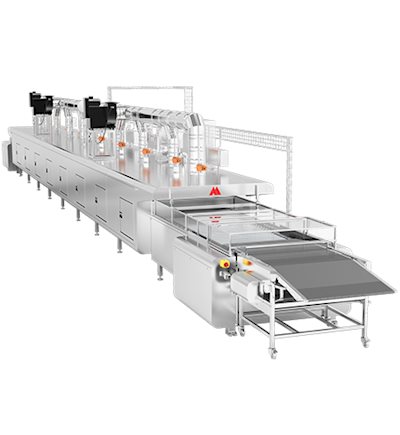

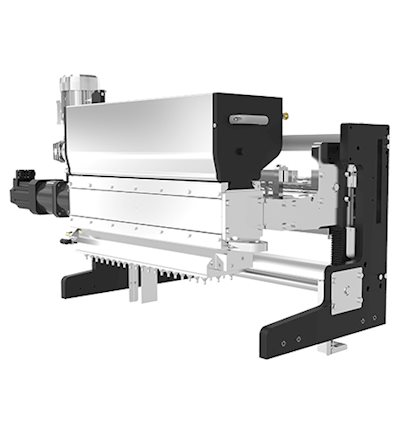

Visit the Aasted Technology Center (ATC) if you want to try out a specific product according to your wishes before making an investment. Here you gain insights into our many machines by experiencing how they are to work with. For instance, try out our diverse and dynamic Alice™ extruder and become acquainted with its many possibilities of creative production. Learn how our several tempering machines can enhance your production line and get up-to-date on revolutionary methods of tempering and handling masses.

Interested in booking the ATC for testing out our equipment?

Contact your local sales agent. The ATC has a fee of €2200 a day.

The ATC represents most of Aasteds equipment for you to experience through direct production according to your needs and desires. You can try out many of our own recipes on for instance protein bars, granola bars or simple yet delicious nougat bars. Observe the initial stage of extruded mass that are transported through a cooling tunnel, cut by guillotine, enrobed with chocolate, and getting through the final cooling – hereafter ready to be packed and distributed. Aasteds dedicated and passionate food specialists are there to walk you through the whole process based on your specific needs and wishes.

Below is a selection of the machinery that you can experience at our Aasted Technology Center.

Technology Center - Related documents

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.