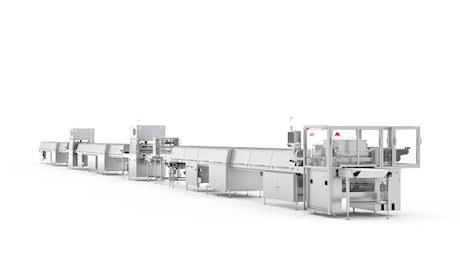

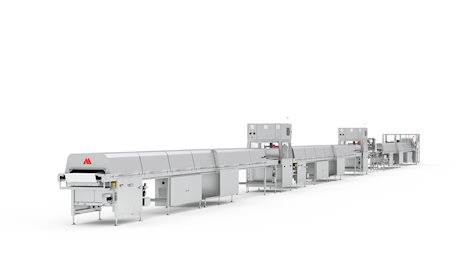

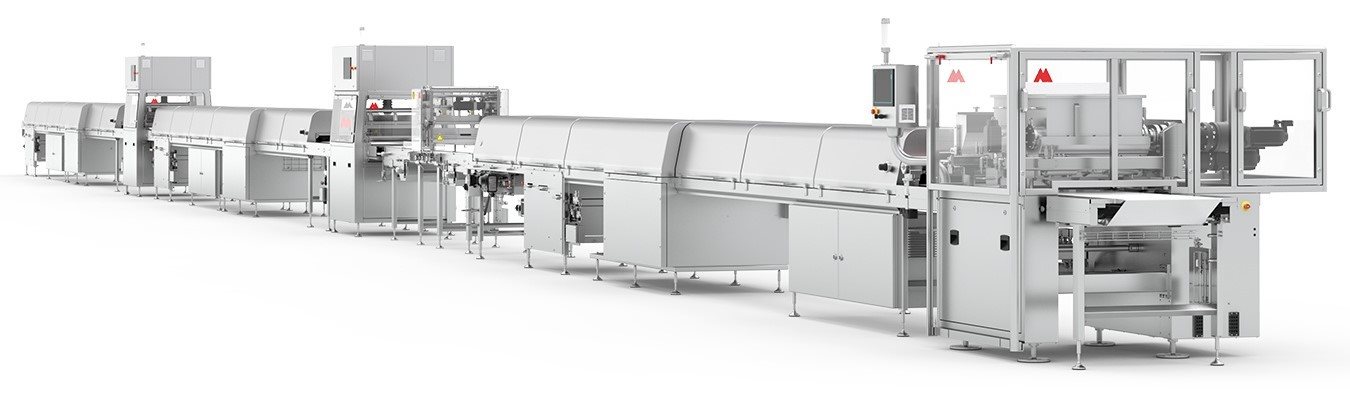

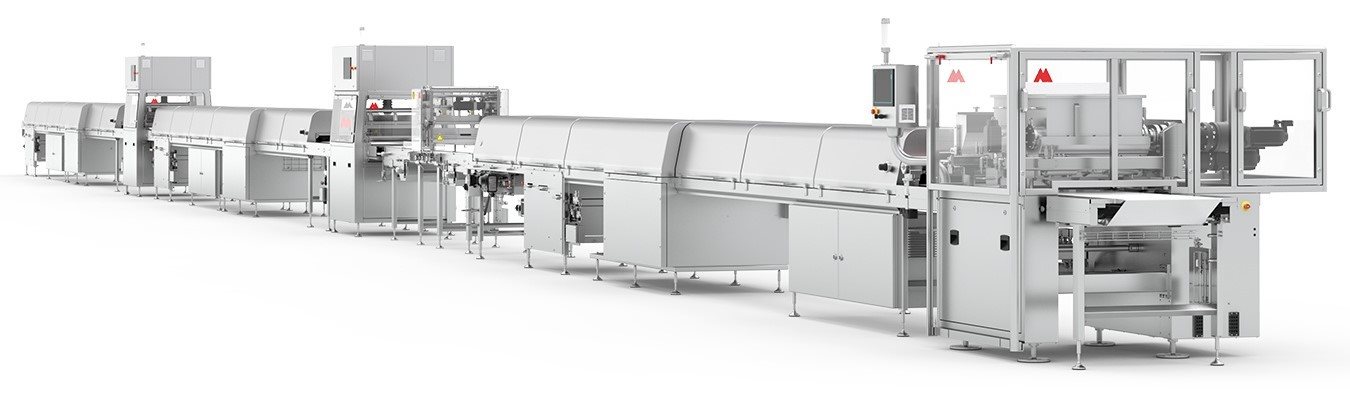

Confectionery Line

The Aasted Alice™ S is tailored for crafting premium protein and energy bars. The Alice™ S boasts high torque engineering, combining durability with minimal moving parts. Its all-stainless steel construction meets the strictest cleanliness and sanitation standards. Enjoy versatility through vertical head movement, fine-tuning your extrusion process. Customize your bars with a variety of forming and cutting tools, and take advantage of a generous belt width, accommodating up to 800mm. Elevate your protein bar production with The Aasted Alice™ S – Your Partner for Quality and Efficiency.

Product Samples

Aerated moulding

Moulding of solid products with or without inclusions, with aeration, tablets, couvertures and combination of chocolate types. Moulding of products with solid centres such as wafers, biscuit centres, big inclusions and bars. Traditional inverting moulding of any shell, surprise and easter eggs.

Triple-shot moulding

One-shot, triple-shot moulding of center or solid filled chocolate articles with various ingredients e.g. nougat and caramel. Also possible in different chocolate types as well as different moulds for different shaped chocolate articles.

Protein bars

Protein bars are popular for their convenience and nutrition. Manufacturing involves molding with various ingredients like nougat and caramel to create delicious and protein-packed snacks..

Alice™ II: Precision and Flexibility in Depositing and Extruding

The Alice™ II depositor and extruder is meticulously designed for both safety and efficiency. Its pressure-controlled feeding system handles raw materials with care, maintaining their structure for precise deposits and minimal deviations. Its modular design allows for quick tool changes, such as pivoting nozzles and wire cutters, adapting seamlessly to your product. This results in better final product quality, increased versatility for various materials, swift production changeovers, the ability to clean the extruder head while the line runs, reduced downtime, and a stainless steel build for easy washdown, ensuring a hygienic solution.