Improve your productivity

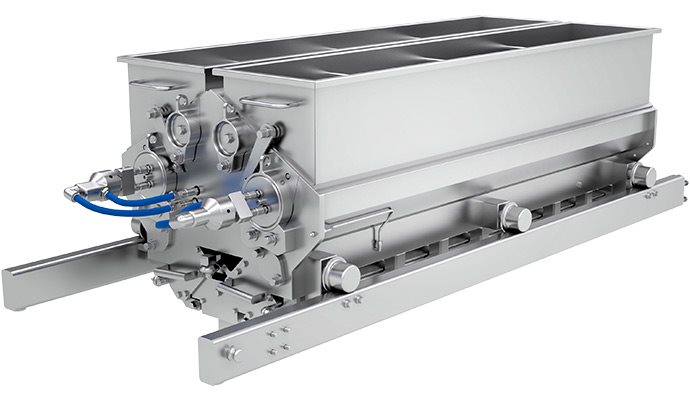

The design of Alice™ II depositor and extruder is built to provide a safe and quick changeover

Alice™ II is extremely gentle when handling raw materials and maintaining their structure due to its pressure-controlled feeding system. It ensures accurate deposits and more minor deviations. The modular design allows you to change tools, like pivoting nozzles, wire cutter, etc., all connect automatically and swiftly vary depending on your product.Innovative design

Off-line function

Gives you the opportunity to remove the head from the line. As the cleaning can be done remotely, the line can run with other machines during the cleaning sequence.

Adapts to your needs

The new Alice™ II can be supplied with a wire cutting system operating at high frequency for a clean cut and accurate position on the belt.

New pump design

The Alice™ II provides a new pump design for dosing masses. The new pump system can handle high amounts of inclusions.

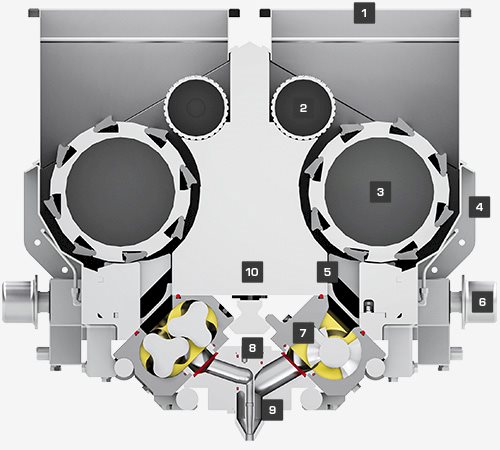

The features of the head

- Easy to remove stainless-steel head [1].

- Assisting feed roller with independent speed control. The function is to gently guide the mass to the main feed roller – the Booster™ technology [2].

- Booster™ feed rollers in all stainless-steel with active wings for highly efficient, slow running and gentle pre-feeding. First in, first out pre-feeding of mass [3].

- Housing. A closed heavy-duty stainless-steel housing with full seam welding [4].

- Measuring volume for detection of pre-feeding pressure [5].

- Rollers for the off-line function [6].

- Pump house/CamRotor™ is optimized for accuracy and gentle handling of ingredients. Choose either the GearPump or the patent protected Sine Pump CamRotor [7].

- Die plate. A broad portfolio of die plates and tools are available to shape and form precisely the product you are looking for [8].

- Nozzles. Fast changeover of nozzles and dies and quick connections [9].

- Heavy Duty mechanism to lift and lower/release the CamRotor™ profiles automatically [10].

Cleaning and maintenance

The Alice™ allows unique removing of the chamber for complete hosedown making cleaning hassle free. In-line cleaning is also possible with dedicated tools assisting you in the cleaning process.

Off-line function for easy cleaning

Alice II has an off-line function that allows you

Alice II has an off-line function that allows you to remove the head while the production is still

running with alternative machines on the line.

This gives you the advantage of being able to

run the line while cleaning it remotely.

QuickShift™ tools

- One-shot

- Two-color mass extrusion and wire cutting or single-mass extrusion

- Wire cutting for large inclusions.

- Sequence depositing

- Single depositing and extrusion

- Depositing with pivoting motion

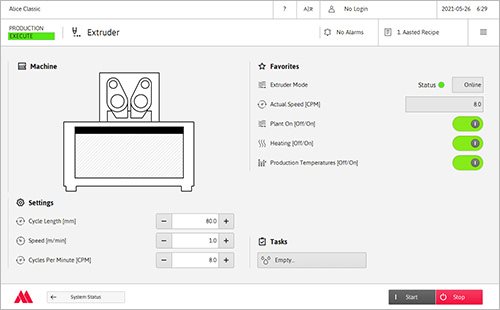

Award-winning intuitive User Interface

While other machines have complicated to use interface, our new patented software has a user-friendly one. The interface is developed for users by users and is specially produced by Aasted for the bakery and confectionery industries.

| LEARN MORE |

Read about the 4 most critical challenges in bakery production

The challenges in the bakery industry are centered around continuously changing environmental hurdles, financial constraints and an increasingly global customer base that are forcing flexibility. These changes demand many industrial bakeries to innovate and associate a more flexible production capacity.

| GET YOUR FREE WHITE PAPER HERE! |

Welcome to Aasted

Visit Aasted Tehnology Center and experience our solutions for yourself.

Aasted Technology Center is fully modernized with the latest processing equipment. Not only can you see the Alice™ II in action, but you can also combine it with other processing equipment. Fill in the form below or contact our sales manager. Start exploring your production possibilities.

Let us inspire you – so you can make delicious possible!

| LEARN MORE |