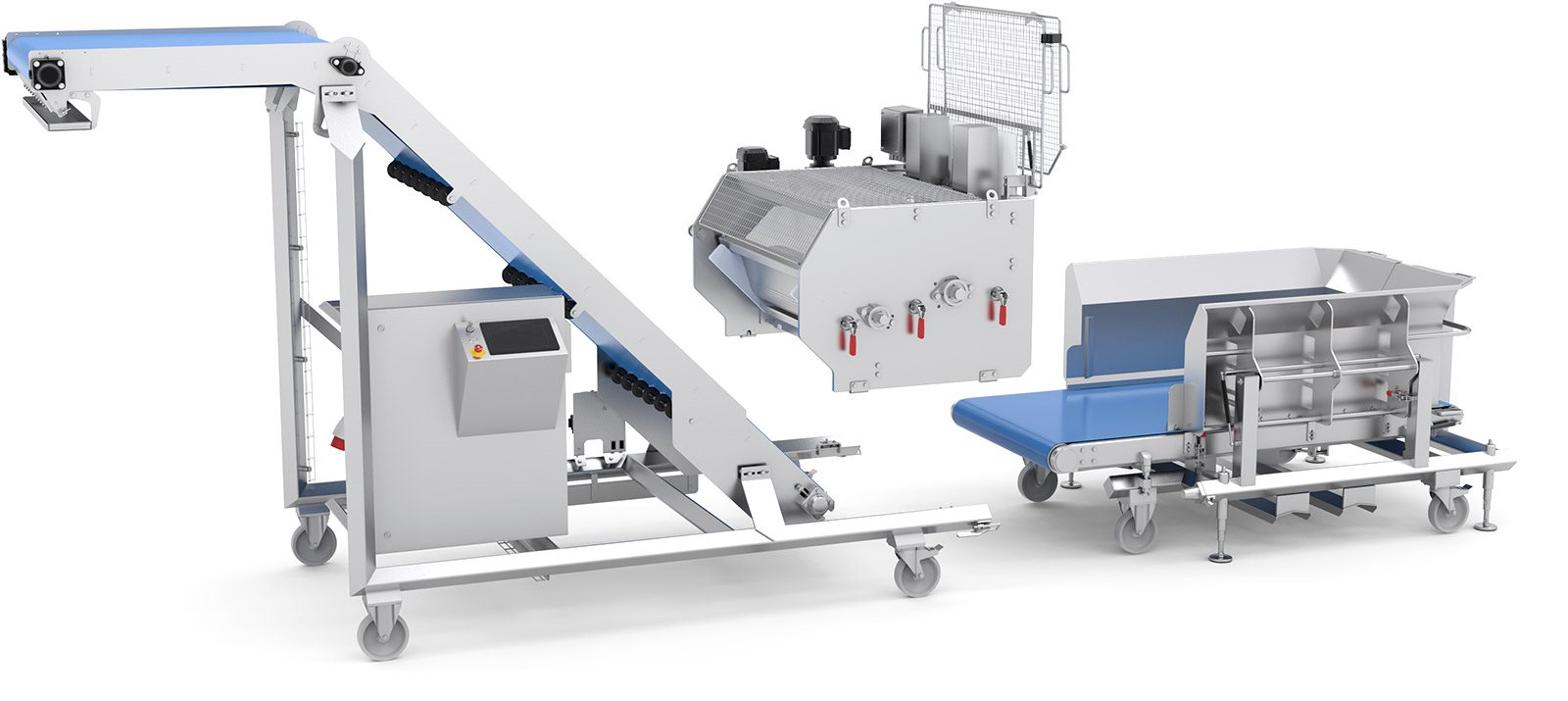

Modular two-belt solution

Provides complete control of the height and speed of dough supply while being extremely gentle

Aasted Dough feeder two-belt modular belt system is the most flexible solution for dough feeding. The machine can be easily taken apart for cleaning, belt change, or product changeover. This solution provides you with a better quality of the final products by securing that your production doesn’t suffer shearing and smearing.Three module setup for easy cleaning

This modular design allows the machine to

This modular design allows the machine tobe easily taken apart and moved for cleaning.

The solution is built entirely in stainless steel

making it completely wash down and compliant

with health regulations and standards.

The three separate modules

Incline conveyor

Choose a conveyor depending on your application. It can incline or deliver mass to lower storage. Comes in different versions depending on your plant layout.

Feeding module

This module comes with an option of a kibbler or a sheether, thus giving you a wider range of dough you can process. It can be lifted to a trolley for easy cleaning and maintenance.

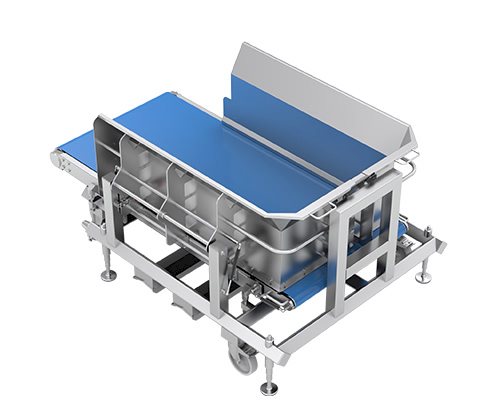

Hopper module

The hopper is robust, simple and has a Tru-Trac® heavy-duty driven belt floor. The machine’s sides are hinged and easy to remove to provide access for cleaning.Extremely easy servicing of the hopper

The modular Aasted Dough feeder hinged

The modular Aasted Dough feeder hingedhopper sides and the quick release and lift

of the conveyor table, makes it extremely

easy to clean and service the machine.

Award-winning intuitive User Interface

While other machines have complicated to use interface, our new patented software has a user-friendly one. The interface is developed for users by users and is specially produced by Aasted for the bakery industry.

| LEARN MORE |

Read about the 4 most critical challenges in bakery production

The challenges in the bakery industry are centered around continuously changing environmental hurdles, financial constraints and an increasingly global customer base that are forcing flexibility. These changes demand many industrial bakeries to innovate and associate a more flexible production capacity.

| GET YOUR FREE WHITE PAPER HERE! |

Welcome to Aasted

Visit Aasted Tehnology Center and experience our solutions for yourself.

Aasted Technology Center is fully modernized with the latest processing equipment. Not only can you see the Aasted Dough feeder in action, but you can also combine it with other processing equipment. Fill in the form below or contact our sales manager. Start exploring your production possibilities.

Let us inspire you – so you can make delicious possible!

| LEARN MORE |