Eriksen Line

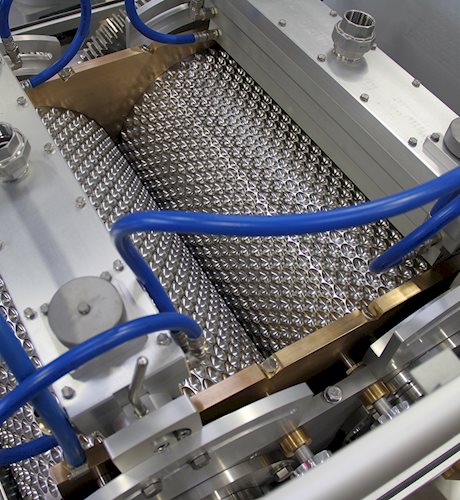

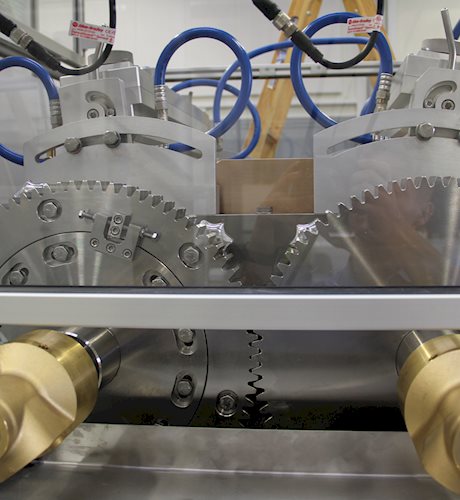

Choose between type ES, supplied with one mobile roller section, a cooling unit, a cooling tunnel including cooling compressor and cooling element as well as a sieve drum. The Type E is different by having a stationary roller section. Both types can be accommodated with additional rollers, conveyors or sieves for future production.

Product Samples

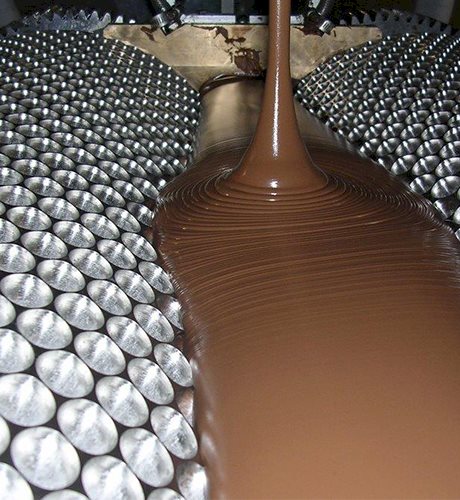

Chocolate eggs

The Eriksen Rollers gently moulds chocolate into uniformly and high quality eggs with a long shelf life. After a cooling process, the eggs can be sugar-coated in various colors.

Chocolate lentils

Chocolate lentils are made in both white, milk and dark chocolate in high speed and capacity. The lentils can be sugar-coated in various colors after a cooling process.

Chocolate balls

With the Eriksen Rollers you can mould uniform and accurate chocolate balls with a cooled precision. After a cooling process, the balls are ready to be sugar-coated.

Experience cooled precision