Feeder Mixer

Feeding and mixing ingredients into a tempered chocolate mass. Enables you to produce products with various inclusions.

The Alice™ Compact is a simple, yet high-performing extruder and depositor. It handles one mass of either high or low viscosity making it easy to operate, clean and maintain. The head movement is available with manual adjustment, automated vertical movement or with automated both vertical and horizontal movement.

Alice™ Compact is a reasonable investment for one mass production. You are provided with a very precise extruder which is easy to control from a real-time adjustable PLC touch screen. The belt width is available up to 1200mm.

The Alice™ brings innovation, quality and creativity to the bakery and confectionery industry. With the Alice™ technology you can produce the finest and most beautiful products in any size, shape and with any filling or inclusion you can dream of. With this technology, the limit will only be set by your imagination.

The Alice™ is designed for any production purpose, whether you need a small lab equipment for product development or for high scale producing 24 hours a day. The Alice™ is designed for bringing creativity and quality to the industry, and is based on technology that gives you the steering wheel.

The Alice™ allows unique removing of the chamber for complete hosedown making cleaning hassle free. In-line cleaning is also possible with dedicated tools assisting you in the cleaning process.

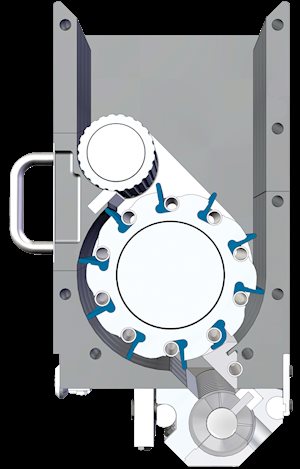

In patented technology the FlexBooster captures and handles masses in the hopper. The technology allows a significantly reduced booster speed compared to traditional methods.

The FlexBooster acts as the main feed roller that guides any volume of mass towards the CamRotor.

The CamRotor is a new and simple three-dimensional impeller. Combined with the FlexBooster the process creates a unique handling of any mass with or without inclusion. Camroter™ creates a gentle suction lift from the mass fed in the FlexBooster™. The CamRotor™ rotates continuously making the extrusion is exceptionally precise.

Together the two patented inventions give you the freedom of being creative while having a flawless end result.

Want to create a great variety of products? Quickshift tools allows you to be creative with the following options:

We also offer you customized tools made just for your requirements. This will enable you to create any shape and inclusion you want.

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.