ChocoMeter+

With the ChocoMeter+ you can calculate the chocolate temper curve and temper index to quality assure you chocolate production.

The feeder can vary the amount of ingredients in proportion to the chocolate mass before being led to the depositor. The mixer is installed between the tempering machine and the depositor. With the feeder you can produce products with large and small ingredients.

The feeding system is designed for gently handling of any inclusions resulting in a beautiful product. The mixers are temperature-regulated, and all parts getting in contact with the chocolate mass are made of stainless steel.

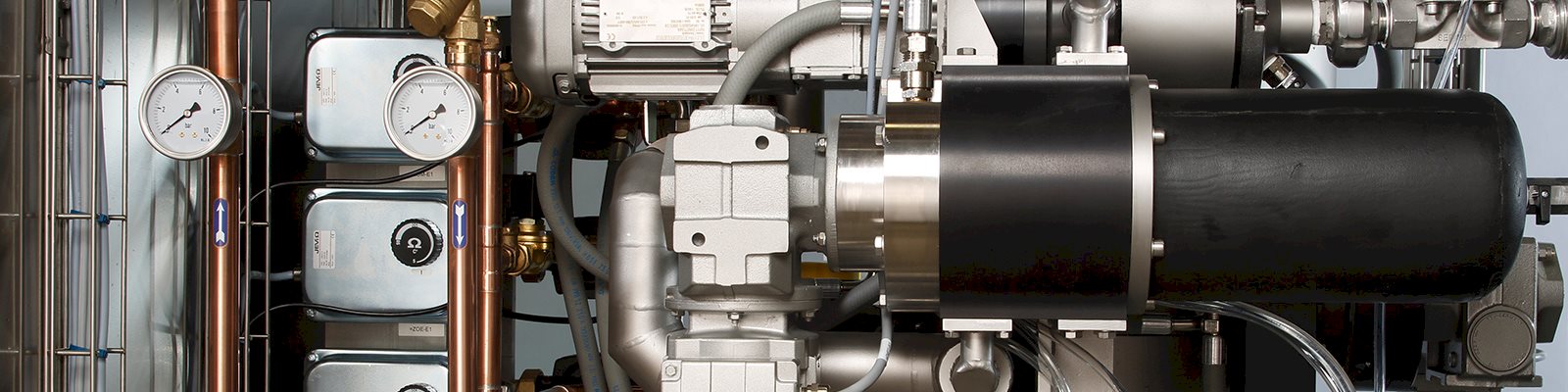

The auxiliary equipment allows you to embed your production with many add-ons, enhancing the production or making your machine more dynamic.

Aasted’s great variety of auxiliary equipment applies to both chocolate, confectionery and bakery machines. The many options enable you to produce at a more dynamic level and to produce a greater variety of products.

The add-on equipment is easily attached and installed to your production line. Discover the many possibilities you have by either upgrading existing machinery or your new Aasted equipment.