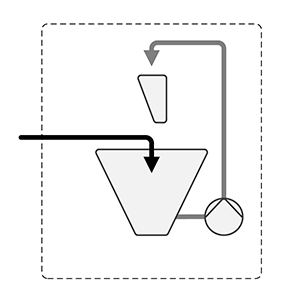

Feeder Mixer

Feeding and mixing ingredients into a tempered chocolate mass. Enables you to produce products with various inclusions.

The newest Aasted Nielsen chocolate enrobing machine for large scale production has a functional design and improved features that provide diverse solutions to common headaches in production.

Band width: 850/1050/1300/1600 mm.

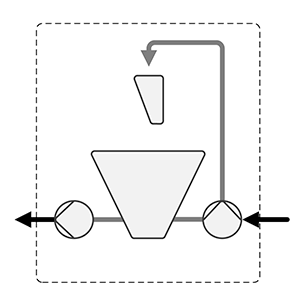

Compound Enrobing

Fast and easy changeover of the enrobing band unit, the pumping and tray unit, reducing the changeover time and downtime. The compound version facilitates the production of a varied portfolio of products.

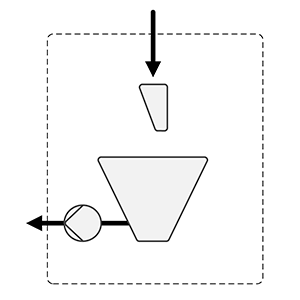

Energy Enrobing

Precise control of the chocolate temperature with the lowest possible energy consumption. The energy version prevents unnecessary chocolate tempering while keeping the high quality of the finished product.

Direct Enrobing

Constantly tempered chocolate that also prevents "build-up" (enabled in combination with the StellaNova tempering machine). The direct configuration prevents blocking complications by keeping a regular flush with freshly tempered chocolate in the machine.

Since 1942 Aasted have created pioneering enrobing technology through our proud Nielsen Series. Innovative and superior engineering is supplying to the bakery and confectionery industry in more than 50 countries.