Feeder Mixer

Feeding and mixing ingredients into a tempered chocolate mass. Enables you to produce products with various inclusions.

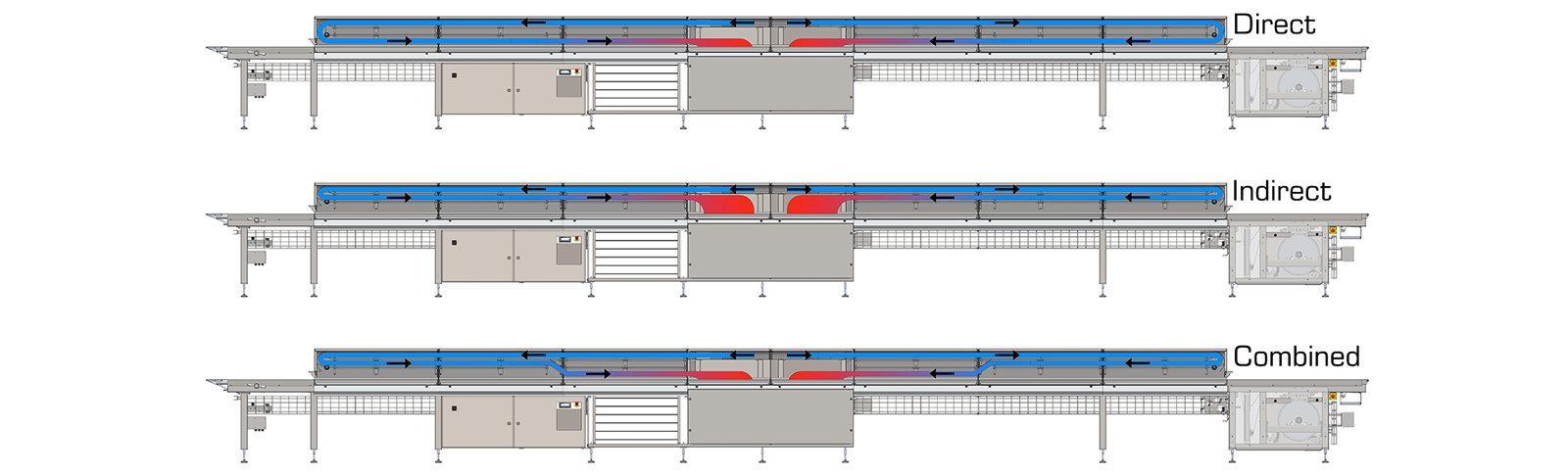

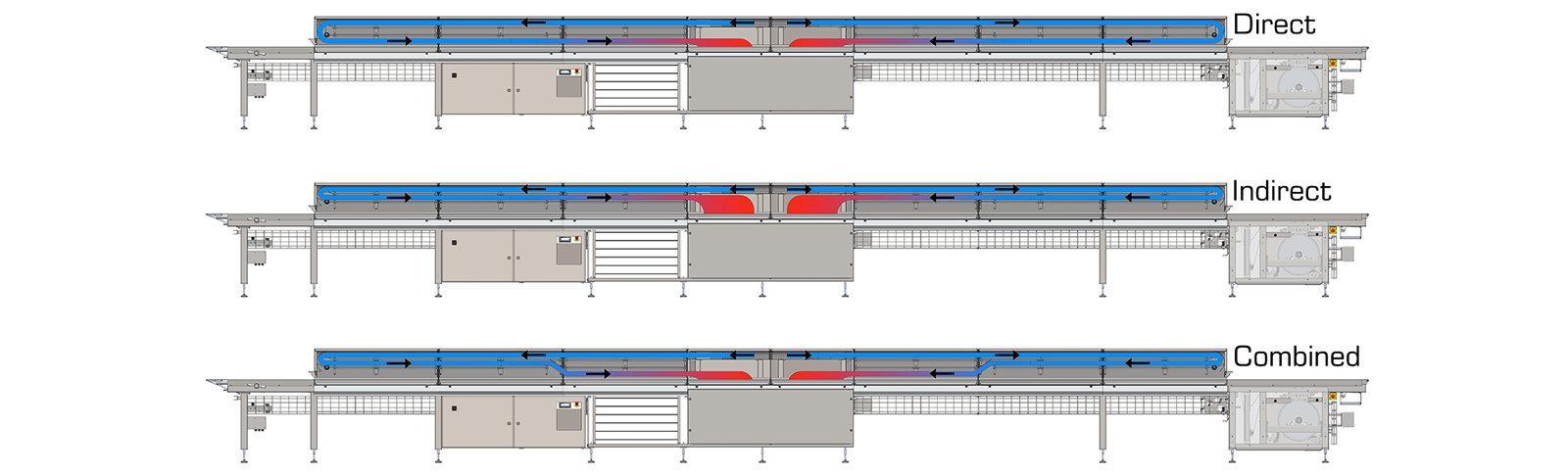

Ranging from 420 to 1800 mm you are supplied with either direct or indirect cooling depending on your product. The specialized cooling system guarantees perfect crystallization, making your product taste, look, break and feel as good as possible.

A flexible and high efficient cooling tunnel in for both chocolate and bakery products. We created a design, which enables you to open each individual hatch making it easy for you to clean and maintain. Available in aluminum, stainless steel or a mix.

Aasteds Nielsen cooling tunnels stand out for their consistent reliability, top performance and its design making them easy to clean and maintain, maximizing uptime. At Aasted we are constantly developing and embedding our machines with innovation, making sure our customers have the utmost newest and best technology.

With the Aasted Nielsen cooling tunnels you are provided with the best technology ensuring your products the best finishing touch for chocolate, confectionery and bakery. Our cooling tunnels are based on many years of experience, know how and passion, ensuring you having the best machinery in the industry.

The cooling tunnels are designed with a focus on simple and clean design – and due to remarkable flexible airflow, the result is an environmentally friendly and energy efficient solution.

A specialized cooling system, re-circulation fan and evaporator work to reduce the tunnel humidity and transform the moisture into dry air, the Nielsen cooling tunnels guarantee a perfect crystallization and cooling process.

For when your product needs to cool softer in the beginning of the process and more powerful in the end, minimizing fat bloom.

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.