Feeder Mixer

Feeding and mixing ingredients into a tempered chocolate mass. Enables you to produce products with various inclusions.

The sanitary design comes in stainless steel with a bottom, shaft and plates that are removable without tools. This makes it ideal for production with many different products, medium/large scale production, where cleaning is needed often. Because of the many removable parts, a total wash down is easy and fast.

The cooling tunnel is easily handled and the sanitary design enables each zone to be opened individually. Together with the removable parts, cleaning or changing bands have never been easier - making your production as efficient as possible.

Aasteds Nielsen cooling tunnels stand out for their consistent reliability, top performance and its design making them easy to clean and maintain, maximizing uptime. At Aasted we are constantly developing and embedding our machines with innovation, making sure our customers have the utmost newest and best technology.

With the Aasted Nielsen cooling tunnels you are provided with the best technology ensuring your products the best finishing touch for chocolate, confectionery and bakery. Our cooling tunnels are based on many years of experience, know how and passion, ensuring you having the best machinery in the industry.

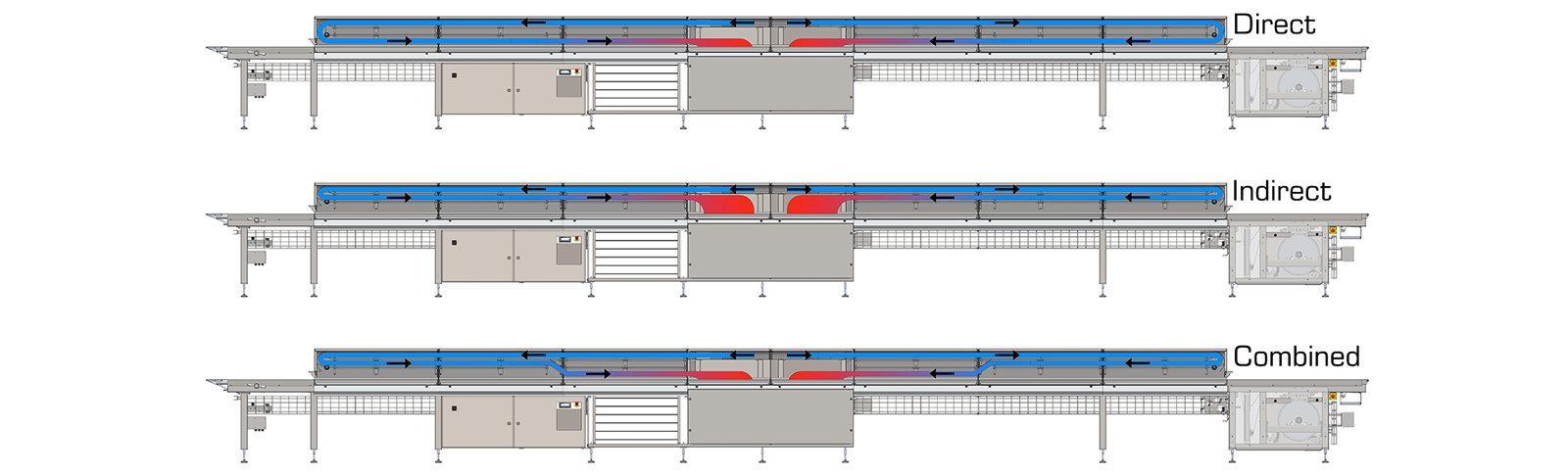

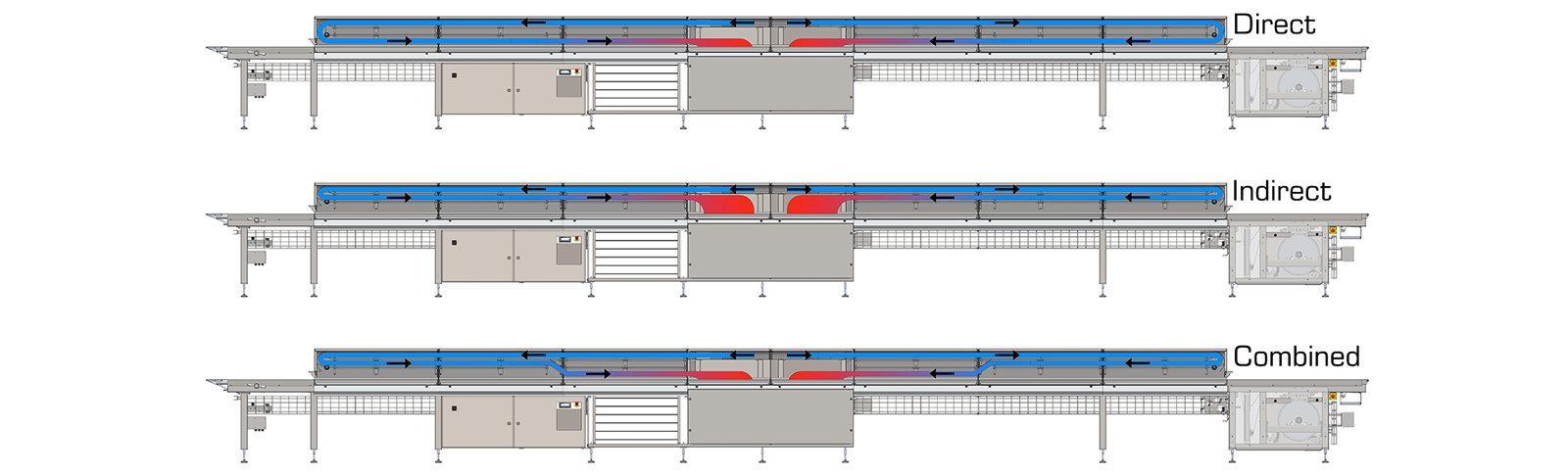

For when your product needs to cool softer in the beginning of the process and more powerful in the end, minimizing fat bloom.

The hinged bottom plates for opening of tunnel allows easy cleaning. All parts are made in stainless steel and are fully washable, as well as the cooling compressor housing - which also is designed for easy cleaning.

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.