Feeder Mixer

Feeding and mixing ingredients into a tempered chocolate mass. Enables you to produce products with various inclusions.

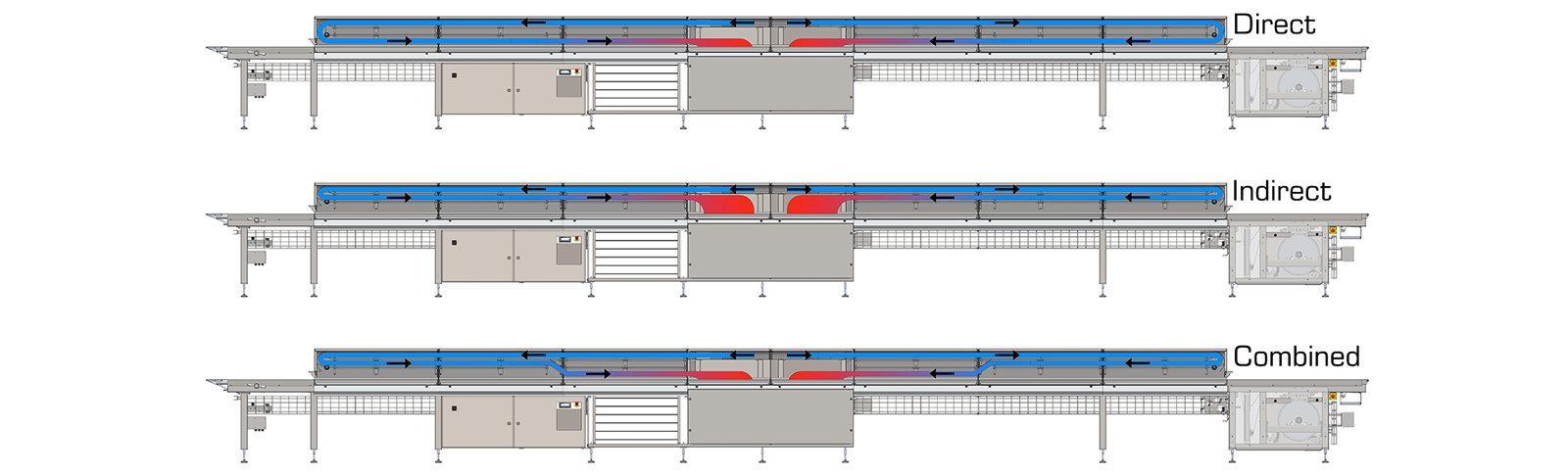

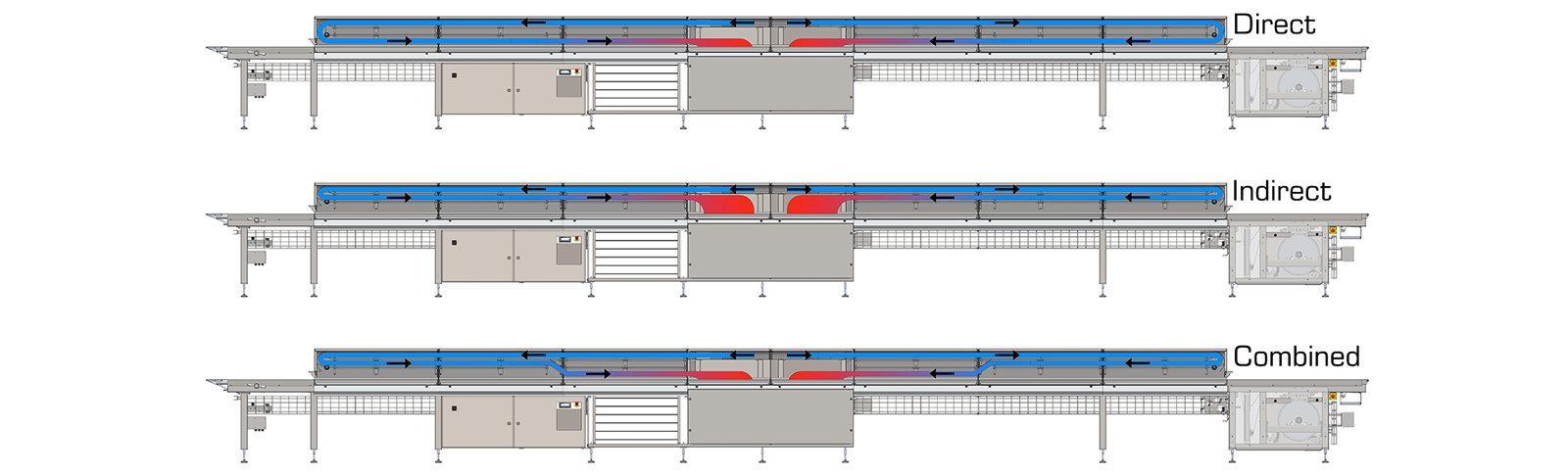

The Nielsen XXL features a special heavy duty stainless steel cover for high capacity cooling with individual opening covers. Designed to operate at 24/7 it provides the option with both direct and indirect cooling depending on your product.

Engineered for high capacity and heavy duty cooling requirements, the Nielsen XXL provides you the correct cooling regardless of your scale, product or requirements. By having a controlled airflow, insulation and cooling cover, the temperature are kept consistent over the entire bandwidth. Band width length comes from 1800 to 2600mm.

Aasteds Nielsen cooling tunnels stand out for their consistent reliability, top performance and its design making them easy to clean and maintain, maximizing uptime. At Aasted we are constantly developing and embedding our machines with innovation, making sure our customers have the utmost newest and best technology.

With the Aasted Nielsen cooling tunnels you are provided with the best technology ensuring your products the best finishing touch for chocolate, confectionery and bakery. Our cooling tunnels are based on many years of experience, know how and passion, ensuring you having the best machinery in the industry.

For when your product needs to cool softer in the beginning of the process and more powerful in the end, minimizing fat bloom.

The Nielsen XXL cooling tunnel features individually opening doors. This feature enables easy access from both sides of the cooling tunnel, making cleaning, accessibility and maintenance trouble free.

The heavy duty stainless steel cover and individually opening doors apply to the entire cooling tunnel.

Download related documents. Do not hesitate to contact us if you can't find the details you are looking for below.