What if ... a new chocolate tempering machine could be a radical improvement of your production?

Should the improvement of your production be used to increase your capacity or to free up space due to a much shorter cooling tunnel?

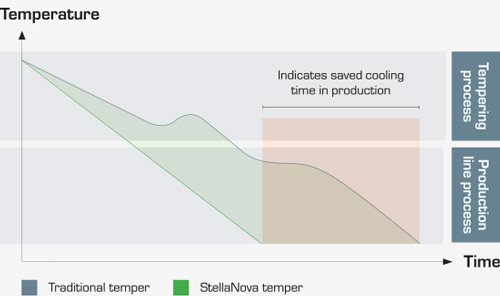

Most tempering machines have a high and not adjustable exit temperature; therefore, it takes a longer time to cool products making the cooling process overloaded and lacking capacity. This potentially leads to consequences such as low throughput and a big footprint, purchasing additional cooling tunnels and high energy consumption due to cooling overload.StellaNova temper and its new technology make it possible to set the exit temperature as low as 27ºC while producing the highest quality small uniform crystals, allowing for complete crystallization.

Because of the low exit temperature, you can reduce up to 40% of your cooling needs, shorten your cooling tunnel length, reduce m2 footprint, and not require additional cooling tunnels.

Achieve up to 40% shorter cooling time

StellaNova gives you full control of the tempering process, the chocolate exit temperature can be lowered 3° degrees without compromising on quality. This reduces the need for cooling time and increases your capacity or allows you to release up space due to a much shorter cooling tunnel.

A breakthrough in the chocolate tempering process

The new StellaNova is one of a kind chocolate tempering machine. It has separate cooling and shearing processes. Meaning you can cool chocolate to a remarkably low temperature and maintain the same amount of crystals. While before unwanted crystals were inevitable, the new StellaNova creates merely the crystals that you need.

Experience StellaNova's temper technology

Experience the new StellaNova, a solution that transforms the tempering process. See how this solution and it's brand new tempering process separates the cooling and shearing processes without sacrificing the quality of your chocolate, reduces energy use and extends your production line output!

Could you also be interested in …

Considerably less production downtime

StellaNova comes with a 75% smaller internal volume, it means that the changeover between productions can be done seamlessly and in less time. This leaves you with a new choice. Is the best thing about the new StellaNova that it can reduce your chocolate waste by up to 75%, or that you will have considerably less production downtime?

| LEARN MORE |

Key to achieving greenest ambitions

The StellaNova gives you a more efficient tempering process, your cooling need can be reduced by up to 40%, and your chocolate waste by up to 75%. This means less energy consumption, reduced CO2 footprint and a new choice for you to make. Is the best thing about the new StellaNova the money it saves you, or that it unlocks your green ambitions?

| LEARN MORE |

Opening of new markets

StellaNova is flexibile like no other tempering machine, you can use one machine for multiple products and outputs. This leaves you with a new choice. What is the best thing about the enormous flexibility of the new StellaNova? That you can use it to increase your capacity, or that you can expand your product portfolio and potentially enter new markets?

| LEARN MORE |