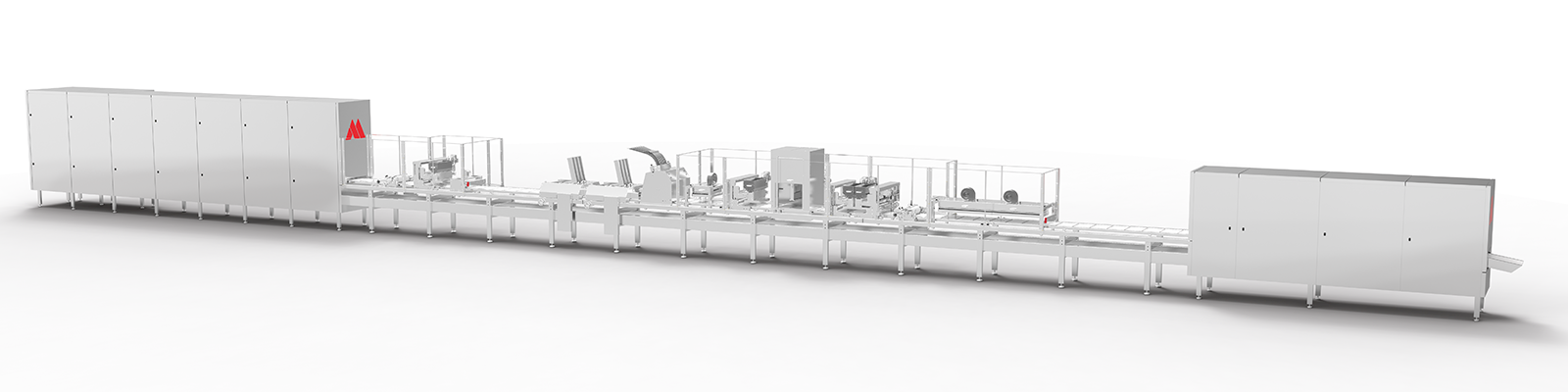

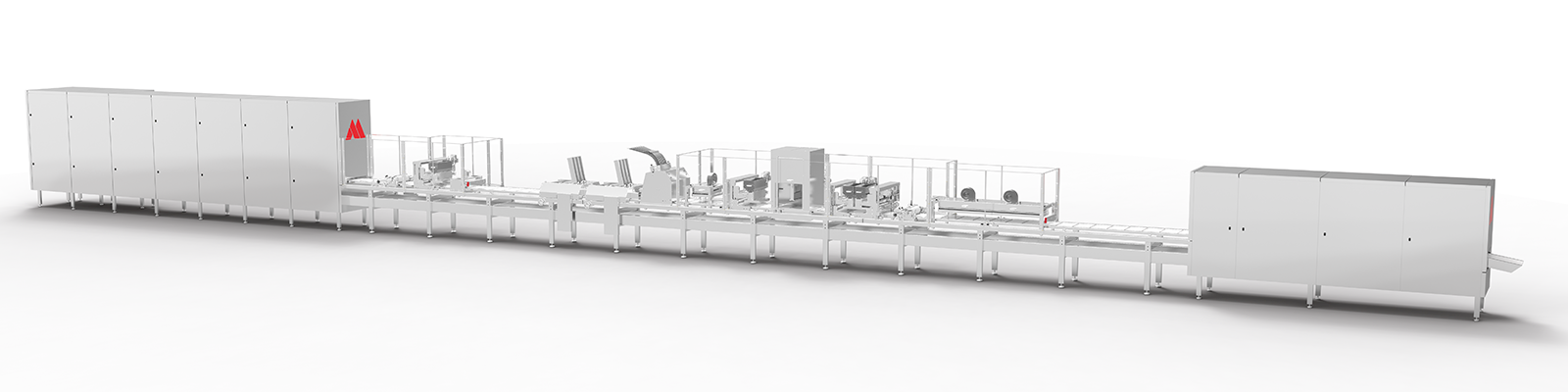

Jensen Line

The Jensen lines have a capacity from 200 – 2,200 kg/hour. Suitable for the production of moulded articles with or without inclusions with various add-on equipment, enabling diversified production.The Jensen lines are designed with low noise driving system with easy interactive HMI.

Characterizing all of the Jensen lines are the design, which is built-up by pre-constructed high quality modules that are tailored to your requirements. Furthermore, the Jensen lines are adapted to low floor-to ceiling height production facilities – compact chocolate moulding lines.Experience the new Jensen Line 'High Mix'

This is a flexible moulding line, adaptable to limited space, thanks to its new cross conveyor, which also enables more possible configurations:

- Two stand-alone lines for simpler moulding applications with an open layout that facilitates the overview of the production

- Or one coherent line for more advanced moulding applications

- Possibility for producing while cleaning, preparing the next batch, or conducting maintenance

- Reduced changeover time

- Single depositing and extrusion

- Increased output capacity with new 700x18" moulds

- For tablets, up to 2100kg/h and for pralines, up to 1800kg/h.

Product Samples

Solid moulding

Moulding of solid products with or without inclusions, with aeration, tablets, couvertures and combination of chocolate types. Moulding of products with solid centres such as wafers, biscuits centres, big inclusions and bars. Traditional inverting moulding of any shell, surprise and easter eggs.

One-shot moulding

One-shot moulding of centre or solid filled chocolate articles with various ingredients e.g. nougat and caramel. Also possible in different chocolate types as well as different moulds for differently shaped chocolate articles.

FrozenCone® Shell

With a FrozenCone® module, the Jensen line makes perfectly shaped cold-pressed shells for pralines, surprise eggs, tablets or any other "shell" product. With a ChocoAssort™ module, a robotic technique transfers the chocolate articles from moulds directly into boxes.

Tailored to your needs

The Jensen line solutions are customized to your production facility, your specific production requirements and most importantly tailored to produce the perfect product at your desired capacity.

In addition to the customization aspect of the Aasted solutions, we provide you many add-on features, making personalization easy and simple for you to choose between. Popular add-on features include our world first patented FrozenCone® and ChocoAssort™.

Jensen Line customer cases

Jensen

The Jensen line is based on the well-known Aasted moulding line technology and built in a modular concept with a possibility of expansion – tailored to your needs.

It can feature open sections giving a possibility to add-on equipment such as depositors, wafer cutters, mould heaters, FrozenCone® units etc.

The Jensen line is perfect for moulding with or without inclusions, with solid centers, traditional inverting moulding, one-shot moulding and FrozenCone® shell forming in capacity of 200 – 2,200 kg/hour.

Jensen Compact

The Jensen Compact is a moulding line in the same modular and high quality concept as the Jensen lines. Designed for small-scale production with a capacity of 230 kg/hour and only requires one operator.

The Jensen Compact line is suitable for solid moulding, with our without inclusions and fillings as well as FrozenCone®.