Alice™ II Extruder

Alice™ II is an entirely stainless steel depositor and extruder. The solution helps you create the best bakery and confectionery products and improves your productivity.

We offer the most flexible machinery on the market, be it dough extruder or confectionery extruder. Our machines give you the freedom to be creative while producing articles with the best results. With Aasted confectionery or dough extruding machines, you are offered the highest quality possible. For every purpose, we have a solution..

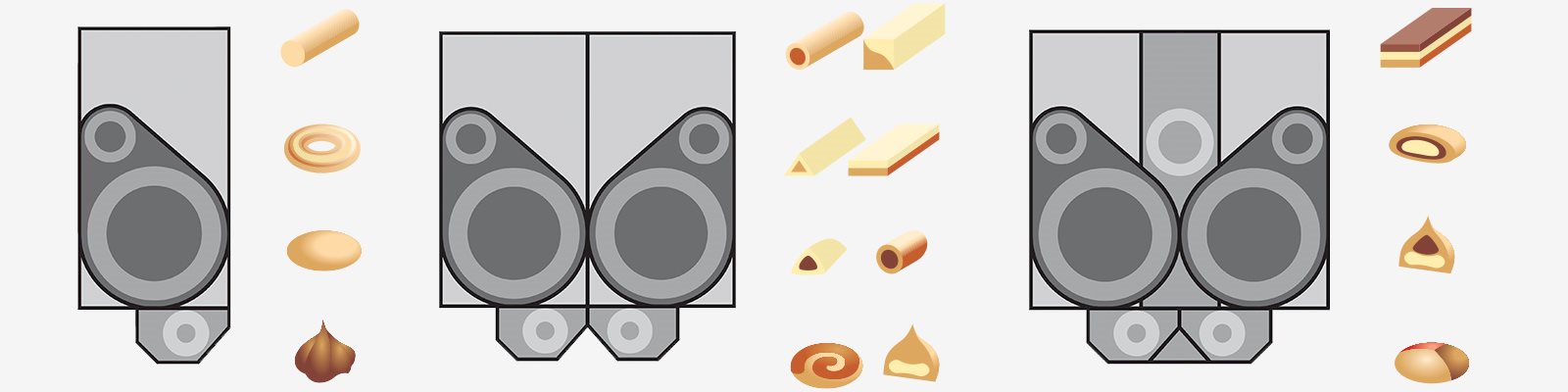

Whether you want to create single, double, or triple mass extruded products, we have the right equipment. Furthermore, you can handle masses with high or low viscosity and even masses with different temperatures at the same time.

Our Alice line allows innovation in a flexible and quality-enhancing manner. In 30 seconds, you can change from, for example, dough extruder production tool to another, allowing various methods of extruding or depositing, giving countless variations of your end product.

The Alice is available in different versions, be it for confectionery or dough extruding, suitable for small, artisan production and large-scale production. Patented technology solutions behind the Alice line allows you to be creative and reduce operating costs while enhancing the total quality of your production line.

Dough extruder technology or depositing is a process of making bakery products. The technique is based on forcing dough through die plates. The firmest dough is often wire cut in order to make a uniform baked product at the end of the process in a bakery tunnel. Wire cutting also makes it easy to create bakery products with inclusions.

Extruding dough often gives you a final product with soft or rounded edges. It is ideal for cookies, cakes, doughnuts, churros, biscuits, or other products that are meant to be round. Depositing of dough is suitable if you require a final product with very sharp edges and precise shape.