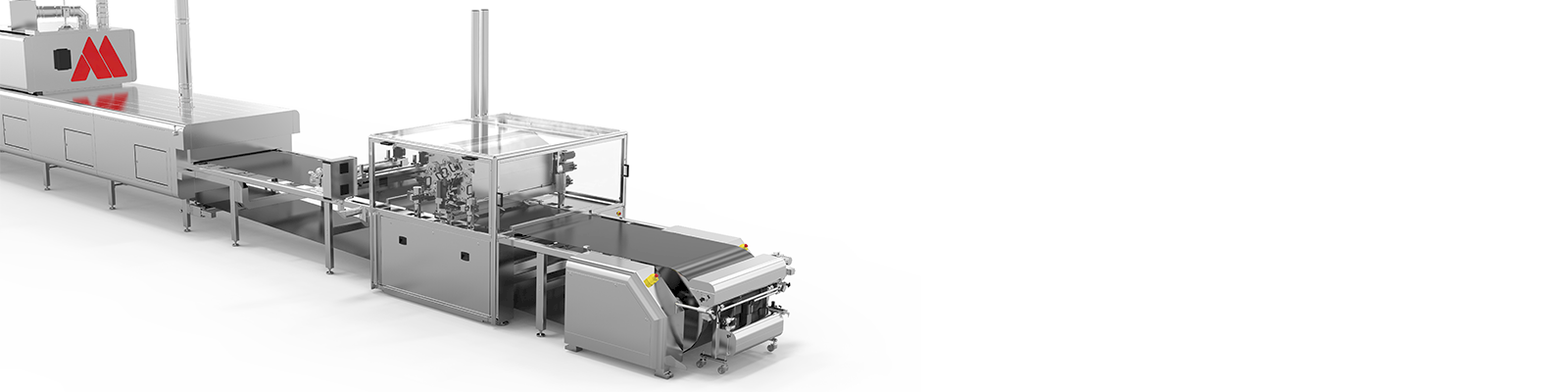

Bakery Line

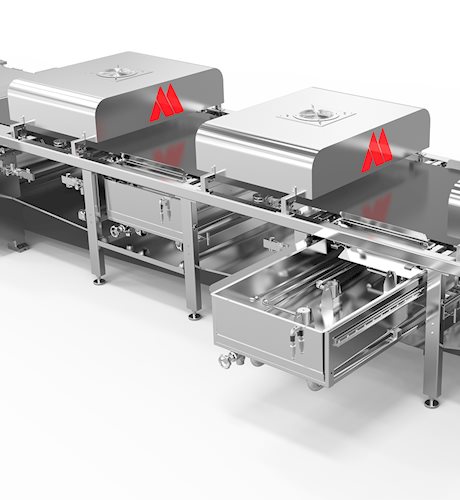

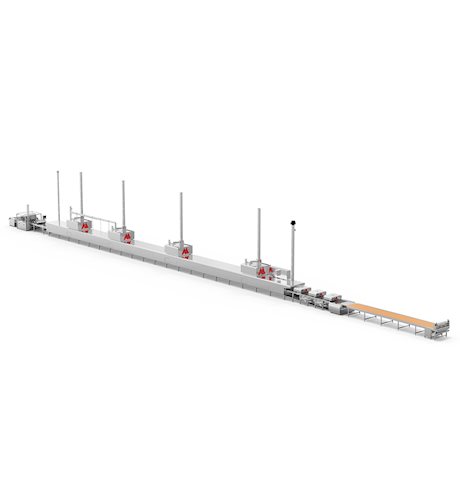

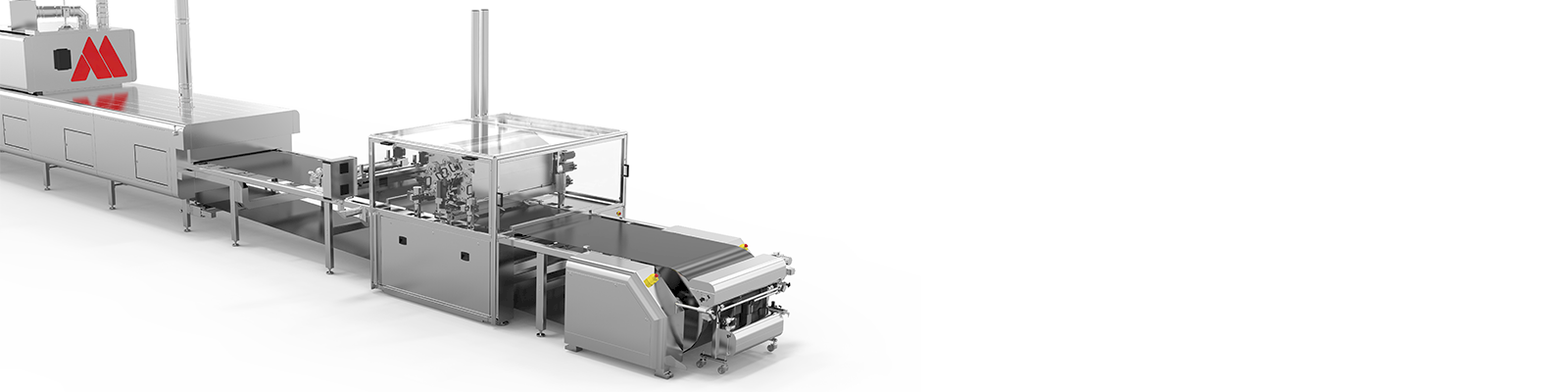

The Aasted Bakery line consists of high-quality elements of our heating, extruding and cooling technologies. The first section (the feed section) consists of a tensioning station, as well as an Alice™ extruder. By having an Alice™ in the bakery line, you will have endless possibilities regarding product development and dynamic production.

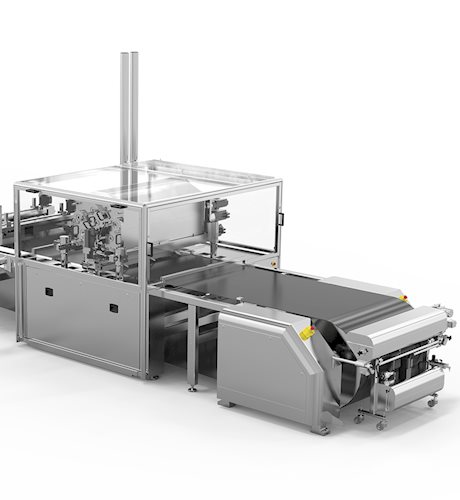

The second section (the oven section) consists of either a DGF, Convection or Hybrid oven from our Conny™ series - depending on the product you want to produce. The third section (the discharge section) consists of a driving station and a cooling system - depending on the products to bake. As always, the line can be customized with different modules in the tensioning station like a depositor or a complimentary enrober after the cooling section.

Product Samples

Depositing with inclusions

The Alice™ allows perfect depositing of cookie masses with inclusions such as fruit, nuts and chocolate as well as single mass depositing. Further, capable of depositing of cookies with up to 3 different masses in one depositing sequence.

Depositing with enrobing

With the Bakery line you can produce any baked product and then give the baked product either full enrobing, partial or bottoming enrobing. The Bakery line handles any mass for baking purposes and gives your products the finest enrobing results.

Triple mass depositing

With an Alice™ in the Bakery line, you can deposit cookies/cakes with up to three different masses. The Alice™ allows single, double and triple mass extrusion/depositing, giving you endless of opportunities within product development.

Customer case

Convinced by the gentle handling of dough, easy changeover between productions and flexibility of the Alice, which qualified it as the best in its class, Joe trusted that our Aasted machinery was the ideal solution for the small-scale industrial productions envisioned by Joe. The bakery line consists of a single head Alice depositor & extruder, a pressing device, an ultrasonic cutter and a tray handling system.

Read about the 4 most critical challenges in bakery production

The challenges in the bakery industry are centered around continuously changing environmental hurdles, financial constraints and an increasingly global customer base that are forcing flexibility. These changes demand many industrial bakeries to innovate and associate a more flexible production capacity.

| GET YOUR FREE WHITE PAPER HERE! |