Welcome to Aasted Academy

The Aasted Academy is a place of innovation where you gain insights into new ways of producing beautiful final products for your consumers to enjoy – and you are invited!

Even today the one-shot technology is rather uncared for by the technical literature. Only sparse information and benchmarks about the practical implementation are available.

Together we will unfold the hidden secrets of the one-shot technology, and provide you with knowledge about how to optimize your production.

Masterclass take-aways

In small dedicated groups, you will learn the basics and many secrets about the one-shot technology. Often overlooked but a crucial factor, we will give you insights into the correct pre-crystallization of the chocolate and fillings. Furthermore, you will learn the best way of cooling your products. You will learn everything there is to know about achieving the best result on the Aasted Nilshot one-shot machine accompanied by experts and prominent guest speakers in Aasted Technology Center.

- Learn the difference between active and passive one-shot

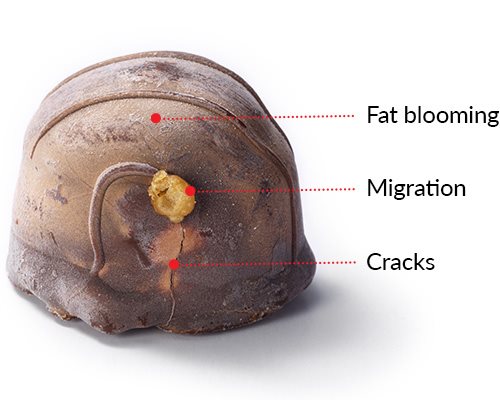

- Gain knowledge on how you eliminate common problems

- Learn how to increase the efficiency of your production

- Pre-crystallization according to one-shot production

- How you can optimize the one-shot cooling process

- Get inspired and learn new ways to be creative

- Network with like-minded

Eliminate common problems

During the 3-day workshop, you will gain insights in how to eliminate common problems when producing with the one-shot technology, both through hands-on exercises and by theory.

- Avoid over-crystallization of chocolate and blocked nozzles

- Controlling temperature of filling and avoid cracked chocolate shells

- Eliminate having air bubbles in the chocolate

- Learn the right amount of vibration of the one-shot chocolates.

Meet the specialists

One-shot specialist

Andreas Maetzler

Workshop host

In the last 20 years, Andreas has done almost all mistakes within one-shot depositing, which means he knows how to perfect the one-shot technology down to the finest detail.

He worked in the chocolate industry for years and grew up in a confectionery family and graduated as Maître Swiss Chocolatier in 1990. He worked as a technical sales consultant for confectionery semi-finished products at Felchlin Switzerland. After that, Andreas was employed at the AWEMA Company for one-shot production plants. He has over 20 years of experience in production plant setup and product development projects. He has become an all-around specialist in the production of chocolates and chocolate specialties where success is based on small details.

With additional postgraduate studies at the HWV in Olten, Switzerland, Andreas is trained in international marketing, business management, and leadership. He worked three years as CEO at Saray International where he built up a sales organization for biscuits and chocolates. He became an expert in the requirements of the confectionery market and understands the challenges provided by the retailer and international supermarket chains to chocolate producers.

Andreas is a member of the working group chocolate at the ETH (Swiss Federal Institute of Technology) in Zurich. He has also been active as a guest lecturer for one-shot technology at ZDS set in Solingen, Germany.

Andreas is very excited to share his experiences and give you insights in new approaches in handling and perfecting the one-shot technology.

Tempering expert

Dennis Holmud

Head of Innovations

Dennis has been in the chocolate industry for almost 20 years and since 2012 he has been head of innovation and chairman for executive R&D senior specialist. Dennis has a background in mechanical and engineering technology where he has acquired an in-depth understanding of mechanical development, construction and automation.

Dennis has a very curious, innovative, engaged and passionate mind and strives to seek out the newest trends in the field of chocolate. This has lead him far in the world of chocolate and especially in the field of tempering. Due to his major optimistic creativity, he has created several innovative solutions and inventions. This has resulted in several patents on various apparatus to make the production of confectionary easier.

A personal message from Dennis:

“I am looking forward to presenting to you the new ways within tempering. Having the right tempering methods is crucial for having a beautiful, well tasting and long lasting product for your consumers to enjoy. Additionally, I look forward to introducing you to new and groundbreaking tempering methods that will make you able to produce products you didn't think was possible!”.

Mikkel Friis-Holm

Award-winning chocolatier, Denmark

Guest speaker

Mikkel owns an artisanal company in Denmark who operates through an agrarian perspective in tune with sustainable values: Microecology of place, single origin native cocoa varietals and a direct trade model. Mikkel Friis-Holm is a trained chef by profession and an explorer by vocation; his trajectory in cooking has strongly influenced his trajectory with chocolate.

Mikkel has sky-high ethics as a focal point for his chocolates. He is a.o. Co-Founder of Direct Cacao, where the chocolate beans are handled directly with the farmers. He is also the author of the book “Chokolade”, an exploration of history and science behind chocolate, along with a rich selection of Mikkel’s best chocolate recipes.

Mikkel has won several International Chocolate Awards and latest in 2018 he received one gold medal and two silver. He is recognized as one of the best in the world in his field.

Sepp Schoenbaechler

Head of Innovation at Max Felchlin AG

Guest speaker

Head of Innovation, Quality & Technology from the fine chocolate manufacturer Max Felchlin AG in Switzerland. His knowledge incorporates diverse areas of semi-finished and finished products, development, quality, sales and acquisitions. He started his food industry career 40 years ago.

In the 90ies he began working with chocolate in cooperation with an international chocolate company, when he developed products for the Japanese brand “Holios” in Australia. He ensured that the strict Japanese quality requirements were implemented. After returning to Switzerland, he continued developing products and managing quality at Hans Kaspar AG. Max Felchin AG then asked him to work for them 18 years ago.

Sepp believes in supporting cocoa farmers at the origin and as such has provided his technical assistance to a project in Granada that has just begun to develop their own cocoa mass from Granada cocoa beans. His goal is the continued development of the best possible taste experience, from every bean while maintaining quality and sustainability.

Marc Pauquet

Head of Chocolate Academy center Istanbul

Guest speaker

Marc's acquaintance with chocolate goes as far as childhood. He learned from his father how to immerse the pralines into the best quality tasty Belgian chocolates. Marc has been the administrator of "Rathauskonditorei", a small café/confectionery shop in Eupen, serving a distinguished customer portfolio, including members of the Belgian government and members of the royal family. Marc also served as executive pastry supervisor of Istanbul Swissôtel The Bosphorus and later assumed the production directorate of the famous Divan Pastry, which operates in the same city.

Nowadays he is working at Barry Callebaut in Turkey as Head of the Chocolate Academy centre Istanbul, a centre of excellence providing training - courses and customer demonstrations focusing on all aspects of Chocolate work and across all trade sectors-Horeca, Pastry, Bakery, Chocolatier.

Workshop program

Day 2

08.00 – Transfer to Aasted

08.30 – Welcome to Aasted

09.00 – The Nilshot hardware

10.00 – Nilshot one-shot praline demonstration

10.15 – How to programme the Nilshot

11.00 – Coffee break

11.20 – New one-shot products (brainstorm)

12.30 – Lunch

13.30 – Factory tour

14.30 – Coffee break

15.00 – The pre-crystallization process

16.00 – Preparation for day 2 (special products)

17.00 – Transfer to the hotel

18.30 – Pickup for typical Danish dinner

22.30 – Transfer to the hotel

Day 3

08.00 – Transfer to Aasted

08.30 – Influence of viscosity and yield value

09.00 – Test run of project (group B)

11.00 – Test run of project (group C)

13.00 – Lunch

14.00 – Guest speaker

15.00 – Fundamental cooling process

15.30 – Discussion of test results

15.45 – End of workshop

16.00 – Transfer to train station

Practical information

Workshop dates

There will only be 8 seats available for each workshops, so please don't hesitate to enroll.

April 23–25, 2019

Guest speaker: Palsgaard A/SCLOSED

October 7–9, 2019

Guest speaker: Mikkel Friis-HolmCLOSED

New dates for 2020 will be announced soon!

Be sure to secure a seat and sign up to our waiting list now! Please use the formular below.

Price

Workshop fee is EUR 990.- excl. VAT.Local transfer from Farum Park Sports Hotel (near Copenhagen) to Aasted. All lunches, dinners and workshop material. The workshop fee does not include hotel- and travel expenses.

Please use the sign up form below. After sign up you will receive a confirmation email with payment options.

Location

All workshops will take place at Aasted headquarter in our Technology Center.

Aasted is located within 20 minutes transfer from Copenhagen city.

Aasted Technology Center

Bygmarken 17

3520 Farum

Denmark

Accommodation

Accommodation is not included in this offer!

We will help you reserve the hotel room simultaneously when you have confirmed and transferred the seminar fee to our account.

We recommend Farum Park Sports Hotel. The hotel is located about 5 minutes from Aasted headquarter.

For more information about the hotel:

http://www.hotelfcn.dk

Thank you for signing up, we will return to you soon with a confirmation email!

Something went wrong while sending the form. Please try again or get in contact with us via mail or phone.

Perfect your one-shot skills

One-shot

Learn how to create one-shot chocolates with up to 4 different colors. You will create beautiful and delicious one-shot chocolates and discover new methods on how to be more creative than ever before.

During this process, you can even bring your own filling and use it on Nilshot with an expert's guidance.

Piped one-shot

Piped one-shot opens the creativity for every chocolate master. With piped one-shot, you generally use ganaches or butter ganaches. We will create different piped one-shot for you to learn and be inspired with.

This method emphasizes having full control of the temperature of the filling – which you will learn to master.