Take advantage of your free energy resources

Save energy and avoid direct emission of greenhouse gases from your production by considering the energy source for your heating and cooling needs.

Heating and cooling from heat pumps is an energy-efficient and well-known technology. However, it is still far more widely used for cooling applications than heating.Heat pumps for heating can save you high operating costs and significantly lower your carbon footprint. Even more interesting is that you can often get the heating almost for free by implementing heat recovery systems. An obvious and cost-efficient place to recover heat is from your cooling applications.

Get inspired and learn more about important considerations when choosing your future energy source.

An efficient energy supply

A lot of process heating can easily be powered by heat pumps or recovered heat. Determine the lowest possible supply temperature to achieve the highest possible system efficiency.

A well-known principle

Heat pumps move thermal energy in the opposite direction of spontaneous heat transfer by absorbing heat from a cold space and releasing it to a warmer one (refrigeration cycle). This enables far greater amounts of thermal energy to be moved than the amount of electricity needed to move it.

Small adjustments make a big impact

A minor adjustment of a few degrees can lead to additional savings of 10-15%. Economically and environmentally, it makes good sense to consider the required minimum supply temperature in your system.

It is important to consider your refrigerant when choosing your heat pump to achieve a high efficiency (COP), but also to avoid large direct greenhouse gas emissions from refrigerants with high GWP. We believe that natural refrigerants are the future-proof choice.

- Electrify processes.

Take advantage of the increasing amount of renewable energy in most power grids. - Use natural refrigerants.

Avoid direct emissions from the use of refrigerants with high Global Warming Potential (GWP) and stay ahead of regulations. - Consider set point and supply temperatures.

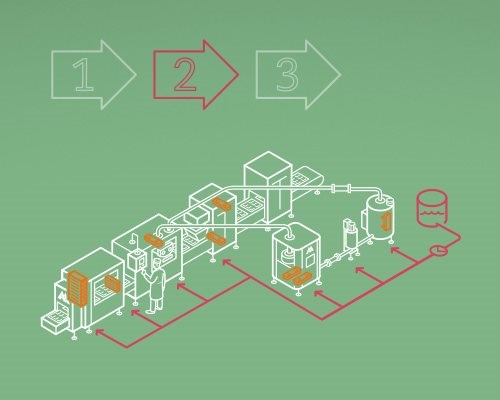

The highest system efficiency is achieved by minimizing the temperature difference in the refrigeration cycle. - Implement heat recovery systems.

Use the “free” heat generated by your cooling production.

Could you also be interested in …

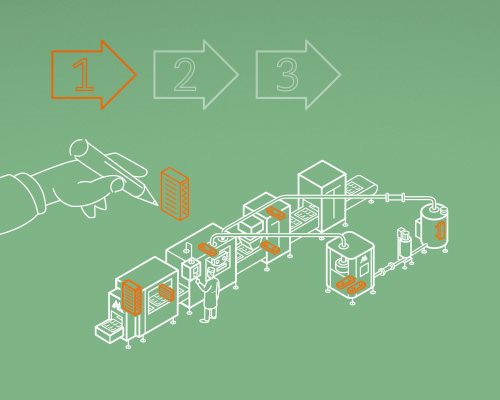

Explore the energy supply for your equipment

Enable a flexible energy supply, allowing you to switch to whichever option is cheapest and most energy efficient today – or that becomes available tomorrow.

| LEARN MORE |

Design for performance, quality and efficiency

Achieve a high and constant product quality and lower energy consumption with a well-designed supply system for your specific production process.

| LEARN MORE |

Learn more about our services in the download center

We aim to ensure the lowest possible emission and production costs through reduced energy consumption. Learn more about how we can help you.

| GO TO DOWNLOADS |